How to Price a Fencing Job: 2026 Pricing Guide + Calculator & Profit Tips

July 2, 2025 - 17 min read

July 2, 2025 - 17 min read

Table of Contents

| TL;DR Fencing contractors face a critical challenge in 2026: accurately pricing fence installation projects while maintaining healthy profit margins. This comprehensive guide reveals how to price a fencing job profitably, from material costs to labor estimation and overhead calculation. Learn proven pricing strategies that help fencing contractors achieve 25-40% profit margins while staying competitive in today’s market. |

KEY HIGHLIGHTS

Smart Fencing Job Pricing in 2026

The global fencing market reached $30.42 billion in 2023 and is projected to grow at 5.6% CAGR through 2030 (Grand View Research, 2024). Yet despite this booming demand, many contractors struggle with profitability.

Industry participants face mounting pressure as gas and electricity expenses contribute over 30% of production costs, while fluctuating raw material prices squeeze margins (Grand View Research, 2024).

The challenge isn’t finding work—it’s pricing it correctly. The US fencing market reached $11.7 billion in 2022, but many contractors still underbid projects due to poor cost estimation U.S. Fencing Market Size, Share & Growth Report, 2022-2030 (Freedonia Group, 2024).

Success in today’s competitive landscape requires mastering the fundamentals of profitable pricing. This guide reveals proven strategies successful contractors use to build a thriving fencing business, from residential installations to complex commercial pricing strategies that protect margins.

Stop leaving money on the table. Use our free service price calculator and discover how accurate pricing transforms struggling contractors into profitable fence installation businesses.

Understanding current market rates helps establish competitive baseline pricing for any fencing job. Here’s what fencing contractors typically charge across different fence types and fencing services in 2026:

| Fence Type | Material Cost (Per Linear Foot) | Labor Cost (Per Linear Foot) | Total Cost Range |

| Chain Link Fence | $8–15 | $10–20 | $18–35 |

| Wood Fence | $15–30 | $15–25 | $30–55 |

| Vinyl Fence | $20–40 | $12–22 | $32–62 |

| Wooden Fence (Cedar) | $25–45 | $18–30 | $43–75 |

| Aluminum Fence | $30–50 | $15–25 | $45–75 |

| Wrought Iron | $40–80 | $20–35 | $60–115 |

Sources: HomeAdvisor, Thumbtack, 2024-2025

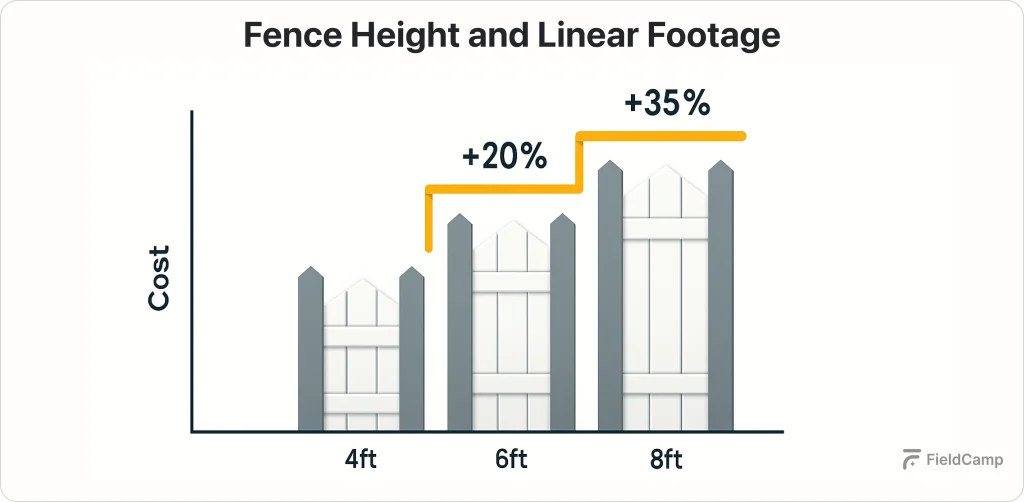

These market rates vary depending on fence height, project requirements, and regional labor costs. Total linear footage significantly impacts the overall fencing project cost.

The choice of fencing material is an important factor that will significantly impact your total cost. Each material has different characteristics affecting both material and labor costs:

Chain Link Fence:

Wood Fence Options:

Vinyl and Composite:

Fence height directly affects both materials needed and labor hours required. Standard heights include:

Total linear footage determines the scope of your fencing project. Longer fence runs often allow for economies of scale in material acquisition and labor efficiency.

A thorough site assessment reveals conditions that significantly impact pricing:

Terrain Challenges:

Soil Conditions:

The most common pricing strategy in the fencing business involves charging per linear foot. This method provides transparency for potential clients and simplifies cost estimates.

Formula: Total Price = (Linear Footage × Material Cost) + (Linear Footage × Labor Cost) + Overhead + Profit

| Advantages | Considerations |

| Easy for clients to understand | Must account for varying site conditions |

| Scalable for projects of any size | Complex projects may require adjustments |

| Industry standard approach |

For standardized fence installation projects, flat rate pricing provides predictable revenue and allows you to reward efficiency.

Formula: Flat Rate = All Your Costs + Overhead Expenses + Desired Profit Margin

Best for:

Some fencing contractors prefer hourly pricing for complex projects where total labor cost is difficult to predict.

When to Use:

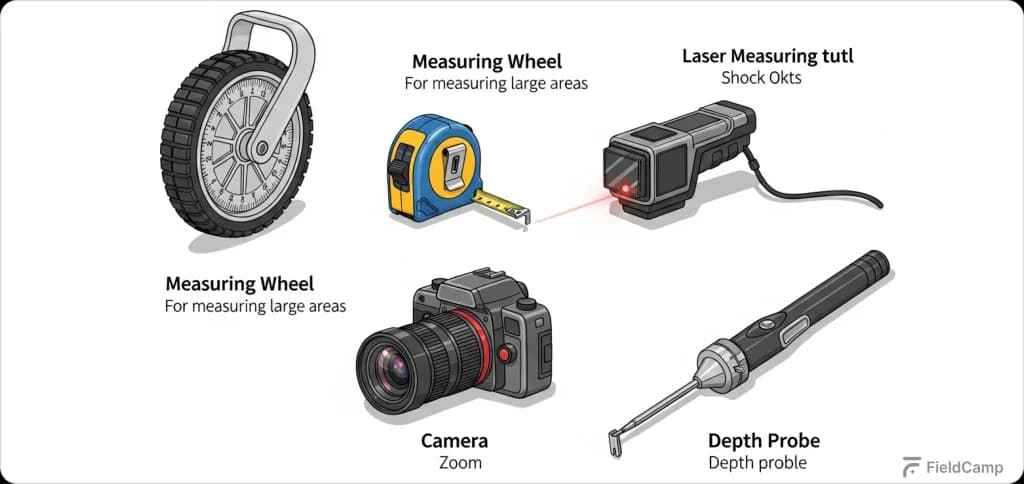

Accurate measurement is crucial for material cost calculation. Use proper measuring tools:

Essential Tools:

Measurement Process:

For a standard wood fence project:

Primary Materials:

Material Cost Example (200 linear feet, 6-foot wood fence):

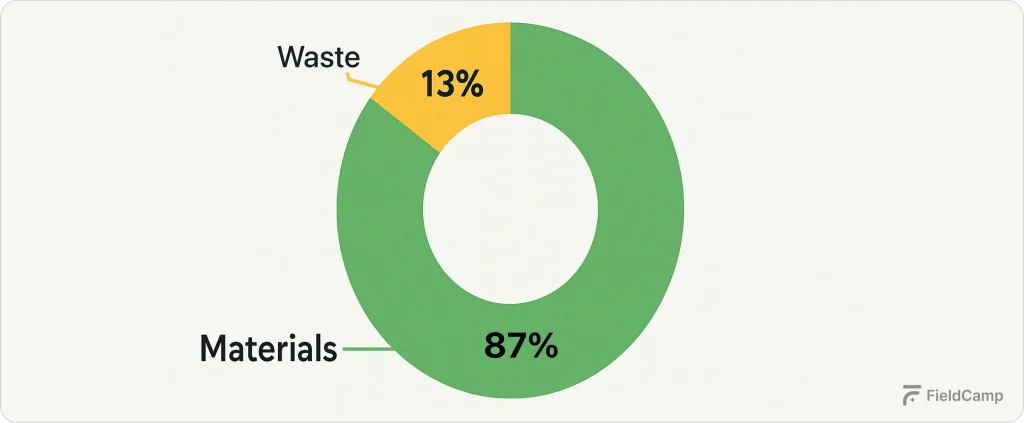

Always include 10-15% waste allowance for cuts, mistakes, and future repairs:

Track Material Efficiently

Stay ahead with real-time inventory tracking and automated low-stock alerts. FieldCamp ensures you always have the right materials on hand, every time.

Estimate labor costs by determining total labor hours needed for your fencing project:

Standard Installation Rates:

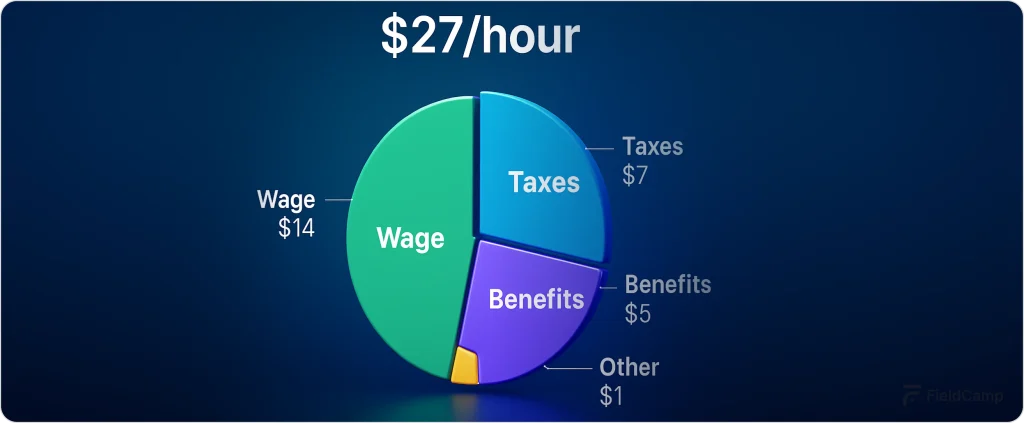

Calculate your fully-loaded hourly labor cost including all expenses:

Base Wage Calculation:

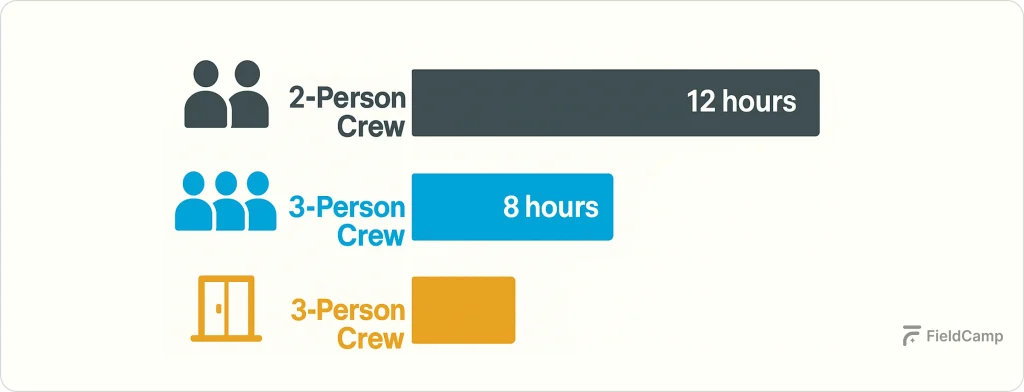

Most fence installation requires 2-3 person crews:

Example:

Use FieldCamp’s team management tools to monitor actual job times and improve future estimates based on crew performance data.

Overhead expenses include all business costs not directly tied to specific fencing projects:

| Fixed Overhead Cost | Monthly Amount |

| Office rent and utilities | $3,000 |

| Vehicle payments and insurance | $1,200 |

| General liability insurance | $800 |

| Equipment maintenance | $500 |

| Software and technology | $300 |

| Variable Overhead Item | Monthly Amount |

| Fuel and transportation | $1,500 |

| Marketing and advertising | $1,000 |

| Professional services | $400 |

| Permits and licensing | $200 |

Monthly Total: Fixed costs + Variable Costs = $8,900

Annual Overhead Costs: $106,800

Determine your overhead rate as a percentage of direct costs:

Apply this overhead rate to each fencing job:

Profit Margin = (Revenue – All Your Costs) ÷ Revenue × 100

Markup = (Selling Price – Total Direct Costs) ÷ Total Direct Costs × 100

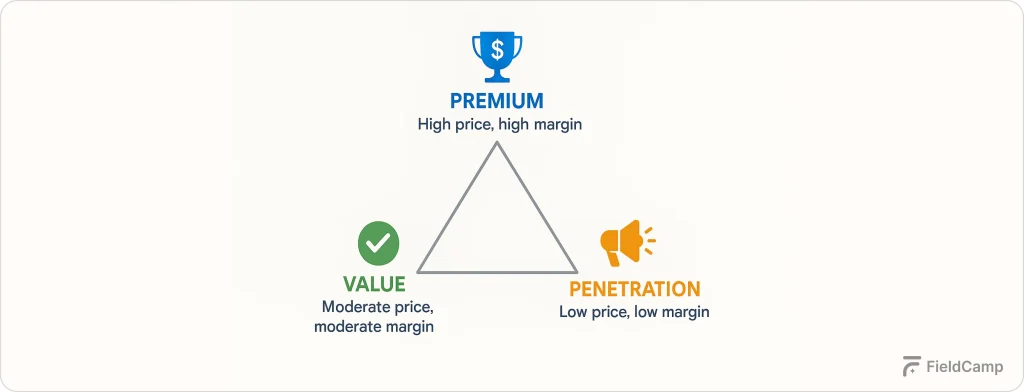

A successful fencing business typically achieves these profit margins:

For a fair price that ensures profitability:

Example Calculation:

To achieve specific profit margins, apply these markup percentages:

| Target Profit Margin | Required Markup Percentage |

| 25% | 33.3% |

| 30% | 42.9% |

| 35% | 53.8% |

| 40% | 66.7% |

Set profitable pricing with FieldCamp’s profit margin calculator that automatically calculates markup and profit margins.

Before conducting a thorough site assessment, gather essential project information:

Client Consultation:

A comprehensive site assessment ensures accurate cost estimates:

Property Evaluation:

Measuring Tools Checklist:

Professional cost estimates should include all project requirements and total cost breakdown. Here is what it is inclusive of:

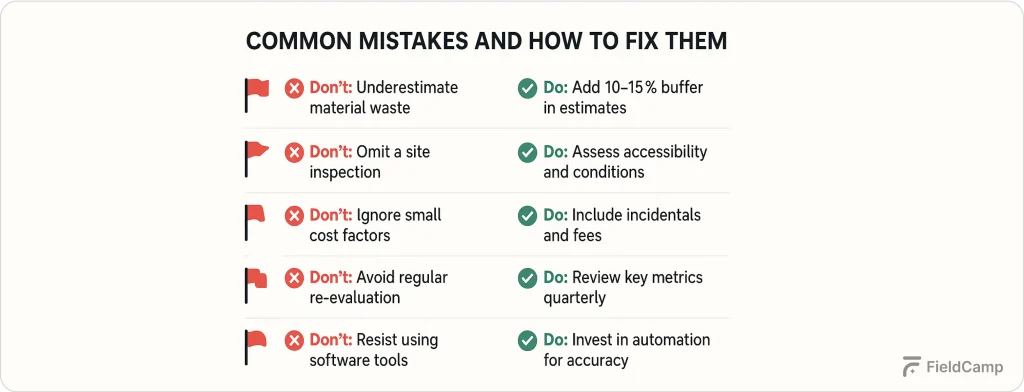

Many fencing contractors underestimate the cost of all the materials needed:

Common Oversights:

Prevention Strategy:

Accurately price labor by considering all factors that affect installation time:

Time Impact Factors:

Calculate overhead rate based on actual annual overhead costs:

Avoid These Mistakes:

Poor cost tracking leads to consistent underpricing. Track actual costs vs. estimates to improve future job pricing and protect your profit margins.

Each job site presents unique challenges that significantly impact costs:

Site Assessment Oversights:

Maintain consistent pricing strategy across all fencing projects:

Track actual costs vs. estimates to improve future job pricing:

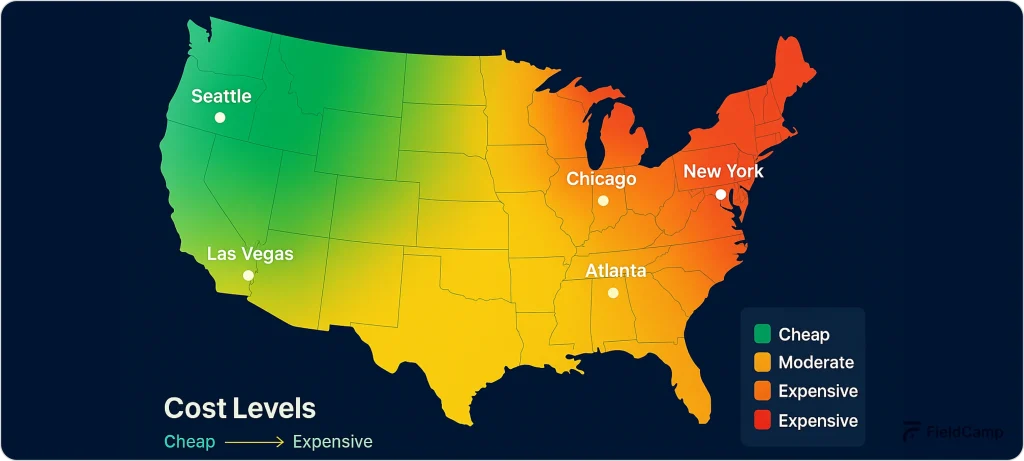

Metropolitan areas with premium pricing due to higher labor costs and material acquisition expenses:

Balanced pricing in suburban markets:

Competitive pricing in rural and smaller metropolitan areas:

FieldCamp provides fencing-specific features that streamline your pricing strategy:

Smart Estimating Tools

Mobile-First Design

Business Intelligence

Complete Business Solution

Run Jobs the Smart Way

From first client call to final payment, FieldCamp simplifies your workflow with tools for estimating, scheduling, tracking, and invoicing—all in one place.

Learning how to price a fencing job accurately requires balancing multiple cost factors while maintaining competitive positioning in your local market. Success comes from understanding your true costs, applying consistent overhead rates, and achieving your desired profit margin on every fencing project.

Key Takeaways for Profitable Fencing Business:

Stop underbidding fencing projects and start maximizing profitability. FieldCamp’s fencing solution provides everything needed to accurately price jobs, manage complex projects, and grow your fencing business.

Start your free trial today and discover why successful fencing contractors choose FieldCamp to price with confidence and win more profitable jobs.

To calculate cost per linear foot, add material costs and labor costs per linear foot, then include overhead expenses and desired profit margin. For example: $15 materials + $12 labor + $7 overhead/profit = $34 per linear foot.

Successful fencing businesses typically achieve 25-40% profit margins. Residential projects often achieve higher margins (30-40%) while commercial projects may be lower (20-30%) due to competitive bidding.

Per linear foot pricing works best for standard fence installation projects as it scales with project size. Use flat rates for complex fence building projects or when additional services are included.

Include escalation clauses in contracts for projects starting more than 30 days out. Monitor material acquisition costs regularly and update pricing when supplier costs change significantly.

Add 10-15% for material waste on standard fencing projects. For complex fence building or first-time installations, consider 15-20% waste allowance.

Review pricing quarterly and adjust for material cost changes, labor market conditions, overhead expense variations, and local competition rates.