How to Price a Junk Removal Job: Complete 2026 Pricing Guide + Calculator

February 24, 2026 - 35 min read

February 24, 2026 - 35 min read

Table of Contents

| TL;DR The junk removal industry has exploded into a $10 billion market, creating unprecedented opportunities for entrepreneurs. This comprehensive guide reveals proven pricing strategies—from volume-based to weight-based models—while covering residential and commercial jobs. Use our pricing formulas and cost calculators to quote with confidence and maximize profits in 2026. |

The junk removal business has exploded into a $10 billion industry, creating unprecedented opportunities for both established junk removal companies and new entrepreneurs entering the market.

According to recent industry data, Americans generate over 292 million tons of waste annually, with the average household producing 1,609 pounds of junk per year (EPA, 2024). This massive demand has led to a 15% year-over-year growth in junk removal services, making proper pricing strategies crucial for success.

Whether you’re launching a new junk removal business or optimizing existing operations, getting assisted by commercial pricing strategies and having a deep understanding of how to price a junk removal job correctly determines the difference between thriving profitability and struggling survival.

KEY HIGHLIGHTS

What You’ll Learn About Junk Removal Pricing in 2026

This comprehensive guide reveals proven pricing junk removal jobs strategies, commercial pricing approaches, digital software for junk hauling companies, and includes access to our free service pricing calculator to help you quote with confidence.

Before diving into the full pricing breakdown, here’s a quick reference for junk removal rates by truck load size in 2026:

| Load Size | Truck Capacity | Price Range | Typical Items | Time |

|---|---|---|---|---|

| 1/4 Truck | 400-500 lbs | $100-$200 | 1-2 furniture items | 30-60 min |

| 1/2 Truck | 800-1,000 lbs | $200-$400 | Bedroom set, appliances | 1-2 hrs |

| 3/4 Truck | 1,200-1,500 lbs | $400-$600 | Garage cleanout | 2-3 hrs |

| Full Truck | 2,000-2,500 lbs | $600-$800 | Estate cleanout | 3-5 hrs |

| Multiple Loads | Varies | $800-$2,000+ | Full house, hoarding | 1-2 days |

Use these ranges as a baseline. Your actual pricing will depend on disposal costs, labor rates, and your local market. Keep reading for the exact 4-step formula to calculate profitable pricing for every job type.

Understanding current junk removal rates helps position your pricing competitively while maintaining healthy profit margins. The junk removal landscape has evolved significantly, with disposal fees rising and labor costs increasing across most markets due to inflation and regulatory changes.

Recent industry analysis reveals that junk removal pricing varies significantly based on job size, location, and service complexity. Most junk removal companies have adapted their pricing structures to account for increased operational expenses while remaining competitive in their local markets.

| Service Type | Price Range | Average Cost | Volume/Notes |

| Minimum charge | $75-$150 | $100 | Single items, 1-2 labor hours |

| Small load (1/8 truck) | $100-$200 | $150 | 60-80 cubic feet |

| Medium load (1/4 truck) | $150-$300 | $225 | 80-120 cubic feet |

| Large load (1/2 truck) | $300-$500 | $400 | 180-240 cubic feet |

| Full truck load | $500-$800 | $650 | 420-480 cubic feet |

The junk removal rate structure reflects several factors that influence pricing. Transportation costs have increased due to fuel price volatility, while disposal fees at landfills have risen by an average of 12% over the past year.

Additionally, most junk removal companies have invested in better equipment and training to handle the growing volume of junk more efficiently.

The junk industry demonstrates remarkable growth patterns that create opportunities for well-positioned service providers:

Environmental regulations have become stricter in many states, particularly regarding electronic waste and hazardous materials disposal. Technology adoption has accelerated significantly, with more companies implementing field service management solutions to optimize routing and improve pricing accuracy.

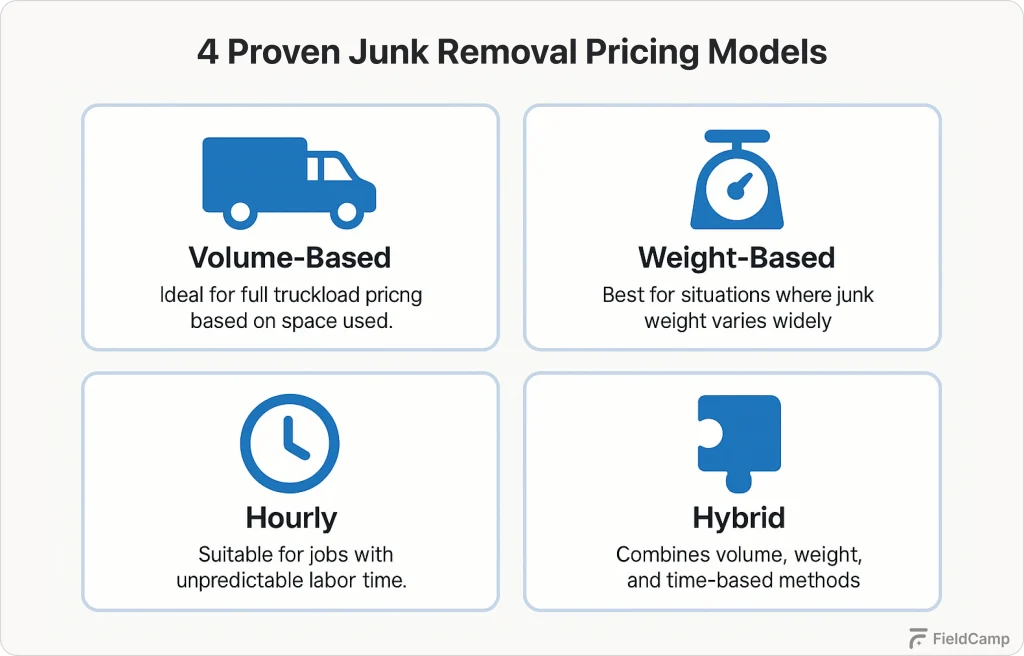

Choosing the right pricing model determines how accurately you can estimate costs, how easily customers understand your rates, and how consistently you maintain profit margins. Most successful junk removal companies use one of four primary approaches:

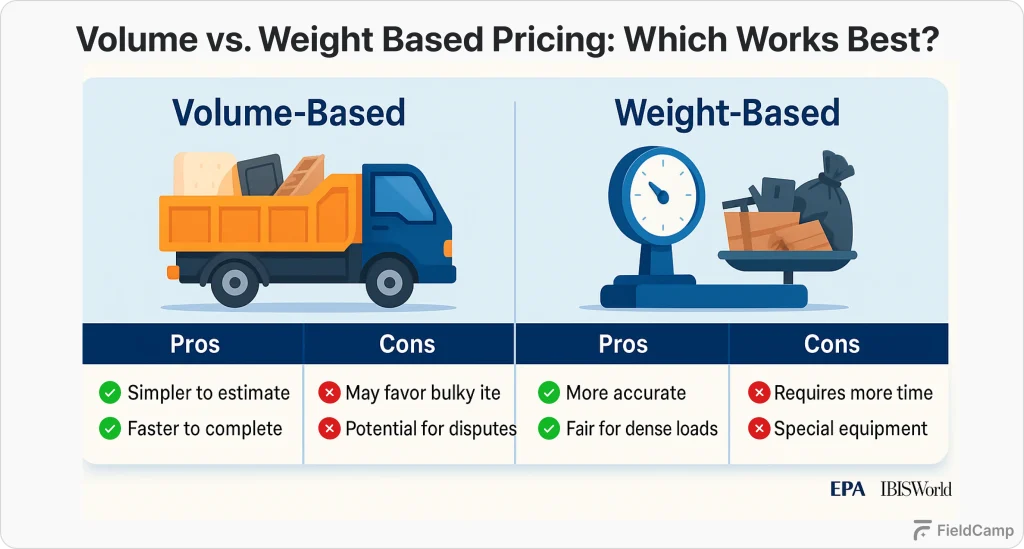

Volume based pricing remains the most widely adopted approach because it provides straightforward customer communication and relatively easy estimation for experienced crews. This pricing model charges based on how much space items occupy in your truck, regardless of weight or time spent on the job site.

How it works: Teams estimate what fraction of truck capacity the junk will fill, then multiply by established rates for that volume tier. Most junk removal companies divide their truck capacity into eighths, with pricing starting at 1/8 truck load and scaling proportionally to full capacity.

Pricing structure example:

| Aspect | Advantages | Challenges |

| Customer | Easy to understand (visual truck capacity) | Hard to estimate accurately for new staff |

| Business | Predictable revenue per truck load | Weight-heavy items may exceed limits before volume is filled |

| Use Case | Ideal for recurring residential clients familiar with the model | Extra trips due to weight limits not included in initial quote |

Weight based pricing charges customers according to actual material weight, typically calculated per pound or per ton. This model aligns pricing directly with disposal costs, which are almost always weight-based at landfills and recycling facilities.

Implementation approach: Teams estimate total weight of materials to be removed, then multiply by per-pound rates plus applicable disposal fees. Some companies invest in portable scales for precise measurement, while others rely on experience-based estimates.

Rate ranges: Most companies charge $0.10-$0.30 per pound for standard materials, with construction debris often priced at $75-$150 per ton due to higher disposal costs and specialized handling requirements.

Pricing formula:

Total Price = (Estimated weight × rate per pound) + disposal fees + labor charges

| Aspect | Benefits | Challenges |

| Fair Compensation | Properly prices heavy materials often undercharged in volume-based models | Estimating weight accurately needs experience or scales |

| Transparency | Reflects actual disposal costs and offers clear cost pass-through to customers | Many customers are unfamiliar with weight-based pricing |

| Customer Behavior | Encourages sorting recyclables due to lower rates at recycling centers | Requires material knowledge to estimate weights without tools |

| Profitability | More profitable for dense/commercial/construction waste streams | Depends heavily on strong disposal facility relationships and understanding of per-ton rates |

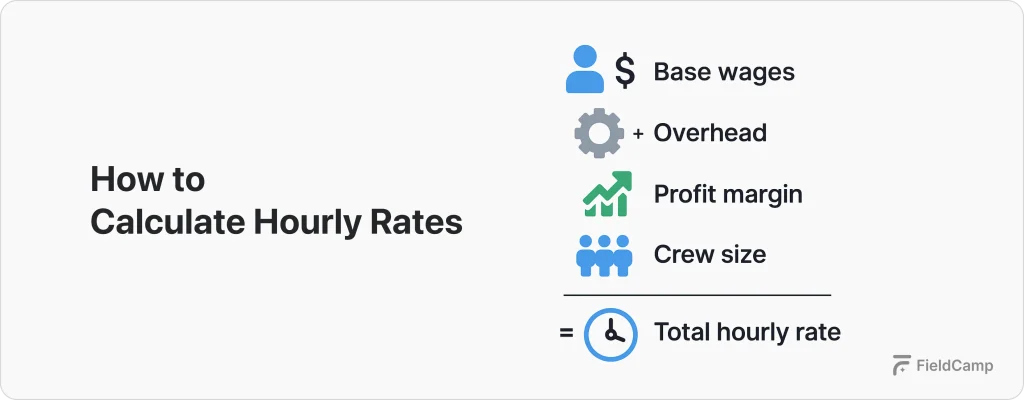

Hourly pricing charges customers based on actual time spent completing the junk removal job, including loading, transportation, and disposal activities. This model provides the most accurate cost recovery for complex or unpredictable jobs.

Rate structure: Most junk removal services charge $75-$150 per hour for complete crews, which typically includes 2-3 workers plus transportation and basic disposal fees.

Hourly rate calculation process:

Hourly Rate = (Labor cost per hour + overhead allocation + desired profit) × crew size

Detailed calculation example:

Ideal scenarios: Jobs with uncertain scope, difficult access situations requiring specialized equipment, hoarding cleanouts with unknown material volumes, or first-time customers where accurate volume estimation proves challenging.

| Aspect | Strengths | Concerns |

| Job Accuracy | Reflects actual time spent, protecting against underestimated job scopes | Requires precise time tracking for fair and transparent billing |

| Fairness | Ensures fair pay for complex or specialized tasks requiring extra care | Customers may worry about inefficiency or time padding |

| Use Case Fit | Ideal for jobs with unpredictable or detailed labor (e.g., sorting, handling hazardous materials) | Large jobs may become too costly, leading customers to prefer flat or volume-based pricing |

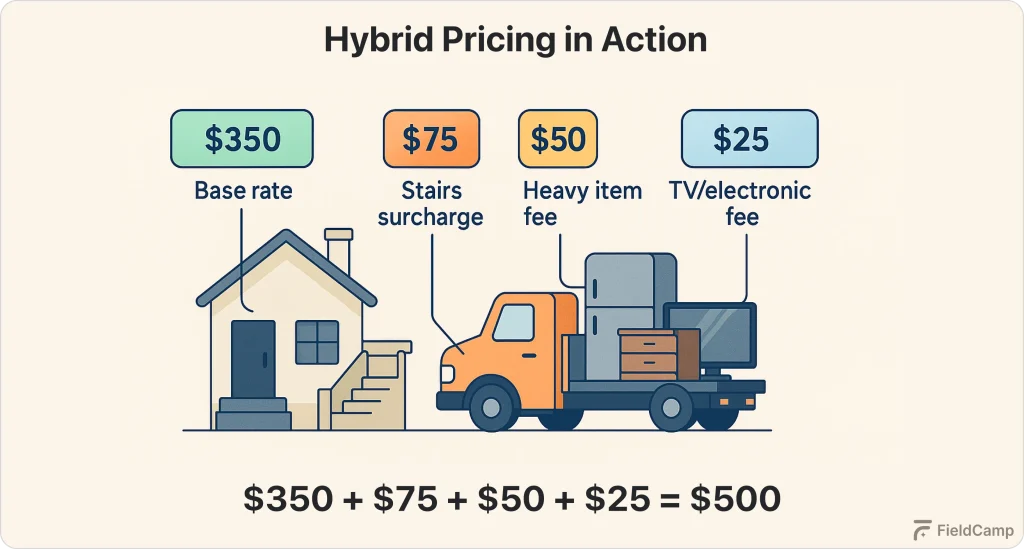

The most successful junk removal companies often implement hybrid pricing that combines elements from multiple models. This approach provides flexibility to handle different job types while maintaining consistent profitability.

Typical hybrid structure components:

Implementation example:

Many field service businesses find that hybrid pricing provides optimal balance between customer satisfaction and business profitability. The approach becomes especially effective when supported by professional field service management strategies that track actual costs and performance metrics across different pricing components.

Commercial vs residential considerations: Commercial junk removal often requires different pricing approaches than residential services. Business clients typically generate larger volumes, have specific scheduling requirements, and may need ongoing service contracts that justify different rate structures.

| Aspect | Advantages | Management Complexity |

| Flexibility | Adapts pricing based on job type, balancing competitiveness and profitability | Requires clear communication of multiple pricing components |

| Fair Compensation | Standard items stay affordable, while special services get properly compensated | Staff must be trained to apply hybrid pricing correctly |

| Customer Clarity | Easier to explain with base rates + surcharges for special handling | Accurate cost tracking needed to maintain margins across varied pricing elements |

While the detailed cost breakdown below covers every variable, here’s the simplified 4-step pricing formula that most successful junk removal businesses use to quote jobs quickly and accurately.

Start by estimating how much truck space the job will fill. This is the foundation of your quote.

Load size categories:

Pro tip: When in doubt, estimate UP. It’s easier to give a small discount at the job site than to ask for more money. Experienced crews can usually estimate volume within 10% accuracy after 20-30 jobs. For phone estimates, ask the customer to send photos of the junk from multiple angles.

Factor in what it actually costs to get rid of the materials:

Example: A 1/2 truck load going to a landfill at $60/ton (estimated 0.5 tons) = $30 in landfill fees + $25 for an old TV (e-waste) + 20% buffer = $66 total disposal cost.

For a detailed breakdown of disposal costs by material type, see our service pricing guide.

Calculate the real cost of your crew’s time — not just their hourly wage:

Example: A 1/2 truck job takes roughly 1-2 hours total. At a $75/hr crew rate = $75-$150 in labor costs.

Not sure how to handle drive time? Read our guide on how to charge for travel time.

Now combine your costs and add your margin:

Full pricing formula:

Job Price = (Disposal + Labor + Variable Costs) × 1.30 to 1.50

Example calculation:

This gives you a healthy profit margin while staying competitive. Adjust the markup percentage based on your local market, higher in expensive metros, lower in competitive or rural markets.

For guidance on setting your hourly rates, check out how much to charge per hour for field services.

Accurate cost calculation forms the foundation of profitable junk removal pricing. Many junk removal business owners underestimate their true operating costs, leading to thin profit margins or actual losses on jobs. Understanding every cost component ensures your pricing covers all expenses while generating sustainable profits.

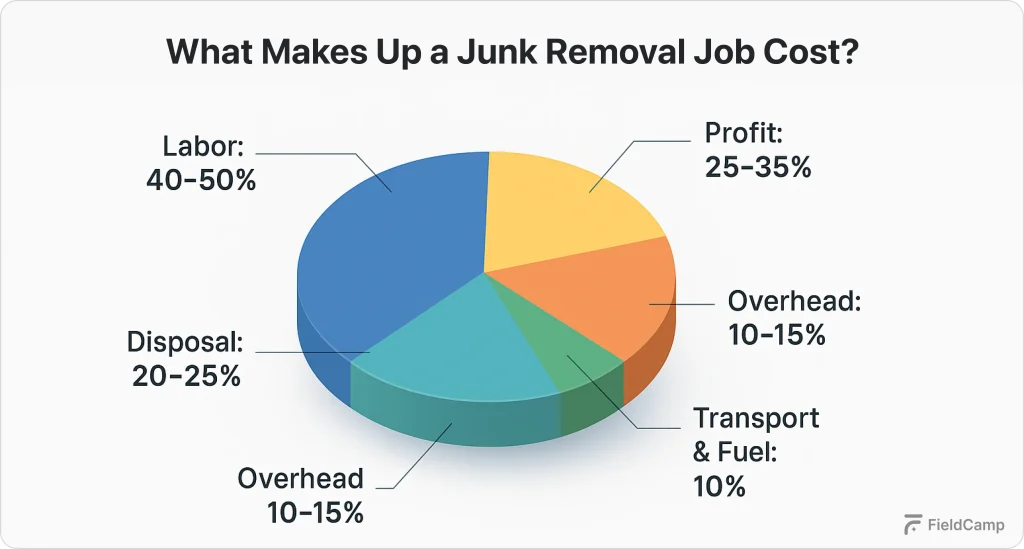

Labor costs represent the largest expense category for most junk removal services, typically accounting for 40-50% of total job costs. The true cost of labor extends far beyond base wages to include taxes, benefits, insurance, and other employee-related expenses.

Comprehensive hourly labor cost calculation:

Total labor cost calculation for a job:

Productivity factors affecting labor costs:

These factors must be evaluated during initial job assessment to ensure accurate pricing.

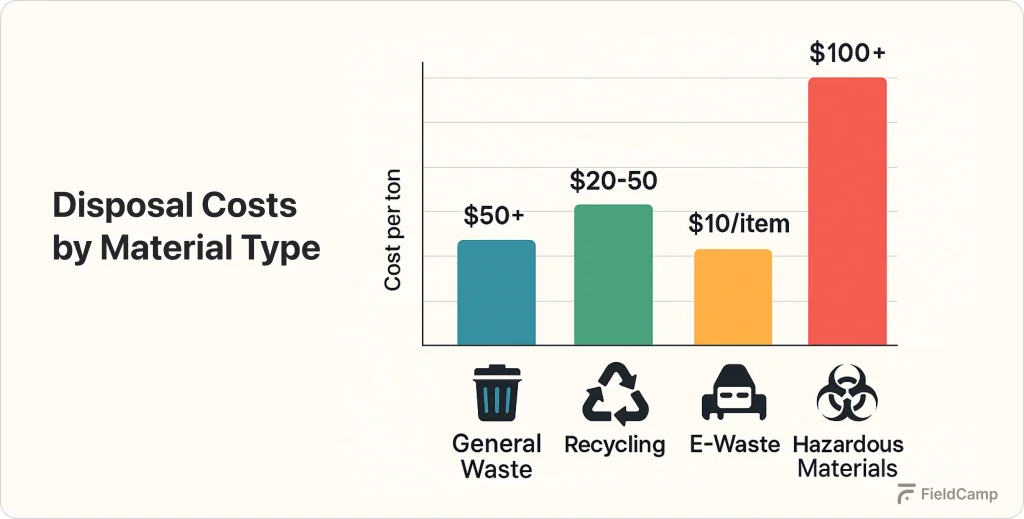

Disposal costs vary significantly based on waste type, local regulations, and facility policies. Understanding your local disposal fee structure is crucial for accurate pricing.

Standard disposal fee ranges by material type:

Disposal cost calculation example:

Disposal fee management strategies:

Variable costs fluctuate with each job but significantly impact overall profitability. These expenses often get overlooked in pricing calculations, leading to cost overruns that erode expected profit margins and create financial pressure on the business.

Variable cost example:

Overhead includes all ongoing expenses not directly tied to specific jobs. Proper overhead allocation ensures these costs are recovered through your pricing structure.

Common overhead expense categories:

Overhead allocation calculation:

Overhead management considerations:

After calculating all direct costs, variable expenses, and overhead allocation, apply your desired profit margin. Most successful junk removal businesses target 25-35% profit margins.

Final pricing formula:

Total costs = Labor + Disposal + Variables + Overhead

Final price = Total costs ÷ (1 – Desired profit margin)

Comprehensive pricing example:

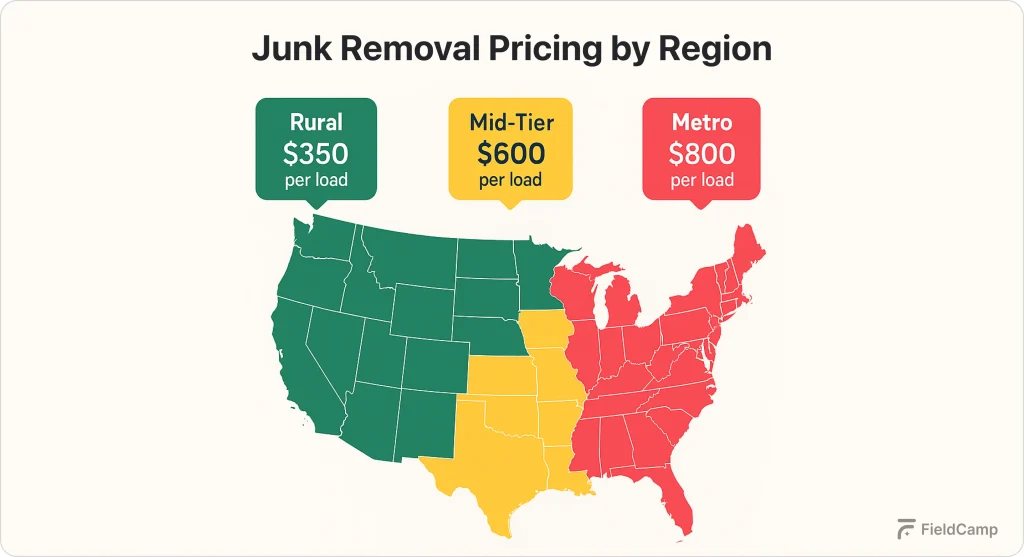

Location significantly impacts what you can charge for junk removal services due to differences in labor costs, disposal fees, competition levels, and local economic conditions.

Major metropolitan areas typically support junk removal pricing that’s 40-70% above national averages due to higher operating costs and increased demand for professional services.

Examples include: San Francisco, New York City, Boston, Seattle, Washington DC, Los Angeles

Pricing characteristics in urban markets:

Typical pricing ranges for metropolitan areas:

Mid-sized cities typically see pricing that’s 10-30% above national averages, balancing moderate costs with healthy competition.

Examples include: Denver, Atlanta, Phoenix, Austin, Nashville, Charlotte

Market characteristics:

Typical pricing ranges:

These markets often represent optimal conditions for junk removal businesses, offering sufficient demand to support profitable operations without the extreme cost pressures of major metropolitan areas. Effective field service optimization becomes crucial for maintaining competitive advantages in these balanced markets.

Rural markets typically see pricing 10-25% below national averages due to lower operating costs but also reduced demand density.

Market characteristics:

Typical pricing ranges:

Understanding these regional factors helps you develop a comprehensive service pricing guide that reflects your local market conditions while maintaining competitive positioning and healthy profit margins. Regular market research and pricing analysis ensure your rates remain competitive as local conditions evolve.

Different types of junk require varying levels of labor, special handling, and disposal methods, which directly impact pricing strategies. Understanding how to price specialty items ensures you maintain profit margins while providing competitive quotes for diverse customer needs and material types.

Appliance removal often requires special handling due to size, weight, and environmental regulations.

| Appliance Type | Price Range | Special Considerations |

| Washers & Dryers | $75-$150 each | Standard removal, recyclable scrap metal |

| Refrigerators | $100-$250 | Freon removal required (+$50-$100) |

| Stoves & Ovens | $75-$175 | Gas line disconnection may be needed |

| Water Heaters | $100-$200 | Heavy weight, possible hazardous materials |

Electronic waste requires specialized disposal methods due to toxic materials like lead, mercury, and cadmium. Many states mandate specific electronic waste recycling procedures, creating additional costs that must be factored into pricing strategies.

Standard electronic waste pricing ranges:

CRT television special pricing: Older cathode ray tube televisions contain significant amounts of lead, making them expensive to dispose of properly. Many disposal facilities charge $75-$150 per CRT TV, costs that should be passed through to customers to maintain profit margins.

Construction debris represents a high-value service category due to weight, disposal requirements, and labor intensity. Most construction debris removal uses weight based pricing due to significant variations in material density and disposal facility requirements.

Pricing by material type:

Hazardous waste requires specialized handling, transportation, and disposal procedures that significantly increase costs. Most junk removal companies charge substantial premiums for hazardous materials or partner with specialized disposal companies.

Common hazardous materials and pricing:

Furniture removal pricing typically uses per-piece rates combined with volume considerations for large quantities.

Typical furniture removal rates:

Working with effective field service management solutions helps track specialty item pricing and ensures consistent profitability across diverse material types and customer requirements.

Different job types carry different pricing. Here’s what to charge for the most common junk removal requests in 2026:

| Item | Price Range | Notes |

|---|---|---|

| Single appliance (washer, dryer, dishwasher) | $75-$150 | Add $50-$100 for refrigerators requiring Freon removal |

| Furniture (couch, dresser, desk) | $100-$300 | Price varies by size, weight, and stairs/access |

| Mattress and box spring | $75-$150 | Some areas charge extra for mattress recycling fees |

| Hot tub removal | $300-$600 | Requires cutting/demolition, factor in 2-4 hours of labor |

| Job Type | Price Range | Notes |

|---|---|---|

| Construction debris | $200-$800 | Requires specialized handling, biohazard considerations, and extra labor |

| Estate cleanouts | $800-$3,000+ | Requires specialized handling, biohazard considerations, and extra labor |

| Hoarding cleanup | $1,500-$10,000+ | Requires specialized handling, biohazard considerations, extra labor |

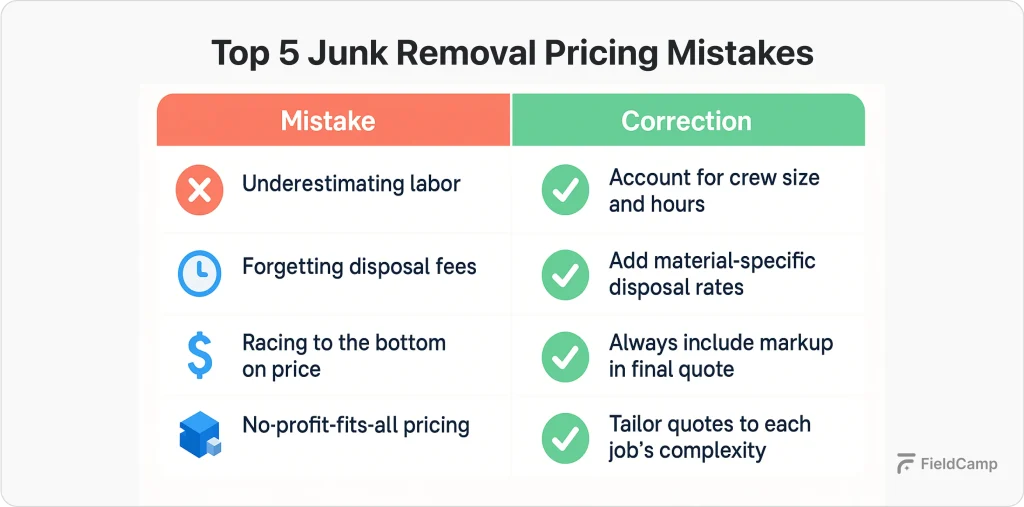

Avoiding common pricing errors protects profitability and builds sustainable business practices. Many junk removal business owners make predictable mistakes that erode margins and create operational challenges, but understanding these pitfalls helps implement better pricing strategies.

The problem: New junk removal companies frequently underestimate how long jobs actually take, leading to labor costs that exceed pricing assumptions. This error particularly affects first few jobs when crews are still developing efficiency and experience.

Time estimation errors compound when access challenges, customer indecision, or unexpected material volumes extend job duration beyond initial estimates. Many new business owners base estimates on ideal conditions rather than typical real-world scenarios.

The solution: Track actual job times meticulously and build a database of realistic time estimates based on experience rather than optimistic projections. Include buffer time for common delays and complications in your standard estimates.

Implementation strategies:

Buffer strategy development: Adding contingency time to estimates protects against underestimating while maintaining competitive pricing. Most successful companies build modest buffers that cover normal variations without pricing themselves out of competitive opportunities.

Commonly overlooked expenses: Many cost components get forgotten during pricing development, leading to profit erosion when these expenses become apparent during job execution or business operations.

Disposal fees for specialty items often exceed standard landfill rates, particularly for electronic waste, hazardous materials, or items requiring special handling. Fuel costs fluctuate and can significantly impact transportation expenses, especially for longer-distance jobs.

Commonly overlooked expenses:

Administrative overhead allocation: Time spent on scheduling, billing, customer communication, and business administration represents real costs that must be covered through job pricing. Many companies underestimate these indirect costs until cash flow problems develop.

The comprehensive cost checklist approach:

Prevention strategies: Create comprehensive cost checklists and review them for every job type to ensure nothing gets overlooked.

The competitive pricing trap: Competing solely on price creates a destructive cycle where companies continuously reduce margins to win jobs, eventually reaching unsustainable levels that threaten business viability.

Price-focused competition ignores value factors that customers often prioritize, such as reliability, professionalism, environmental responsibility, and service quality. Many customers willingly pay reasonable premiums for superior service experiences.

Value differentiation strategies: Focus on value propositions that justify pricing rather than competing purely on cost. Professional appearance, reliable scheduling, environmental responsibility, and quality service create competitive advantages beyond pricing.

Better competitive approaches:

The “worth it” positioning: Develop messaging that acknowledges you’re not the cheapest option while clearly explaining why your services provide better value. Most customers understand the relationship between price and quality when properly communicated.

The problem: Using identical pricing approaches for all job types ignores significant differences in complexity, risk, and resource requirements between different customer segments and material types.

Residential junk removal, commercial projects, construction debris, and specialty materials all have different cost structures, risk profiles, and customer expectations that warrant different pricing approaches.

Situation-specific pricing models:

Customer segment considerations: Business customers often have different pricing expectations and decision criteria than residential customers. Understanding these differences helps develop appropriate pricing strategies for each segment.

Development approach: Create specific pricing models for major customer categories and job types rather than applying universal rates that may not accurately reflect actual costs and value provided.

The static pricing problem: Maintaining the same pricing as costs increase leads to gradually eroding profit margins.

Quarterly pricing review process:

Timing and implementing price increases requires careful consideration of market conditions, customer relationships, and business needs. Strategic price adjustments maintain profitability while preserving customer satisfaction and competitive positioning.

Cost inflation impacts: When disposal fees, fuel costs, or labor expenses increase significantly, pricing adjustments become necessary to maintain profit margins and business sustainability.

Market demand changes: High demand periods or capacity constraints in your market may support price increases, particularly for premium services like same day junk removal or emergency response.

Competitive landscape shifts: When competitors raise their rates or new premium service providers enter the market, opportunities may exist for strategic pricing adjustments.

Service enhancement justification: Adding value through better equipment, expanded services, or improved customer experience can justify price increases that reflect enhanced value provided.

Gradual vs. immediate increases:

Small, gradual price increases often meet less customer resistance than large sudden changes, allowing for market adjustment and customer retention.

Customer communication approaches:

New vs. existing customer treatment:

Consider implementing price increases for new customers while maintaining current rates for existing customers for a transition period to preserve relationships.

Service tier restructuring:

Instead of raising all prices, consider creating premium service tiers with enhanced features while maintaining standard service at current rates.

Peak season adjustments: Many junk removal businesses experience seasonal demand peaks during spring cleaning, moving seasons, and post-holiday periods that may support temporary price premiums.

Off-season incentives: Offering modest discounts during slower periods can maintain steady business flow while preserving standard rates during normal demand periods.

FieldCamp’s comprehensive platform transforms how junk removal businesses operate, combining advanced pricing calculators with complete business automation. Built specifically for field service companies, FieldCamp eliminates the guesswork from pricing while streamlining every aspect of your operations.

The platform’s labor cost calculator automatically factors in wages, payroll taxes, benefits, and overhead costs to ensure accurate job pricing. Combined with the profit margin calculator, you can instantly determine optimal pricing that guarantees profitability on every junk removal job.

Core FieldCamp Features for Junk Removal Success:

Complete CRM Integration

Advanced AI Scheduling & Route Optimization

Professional Quote Generation

Real-Time Reporting & Analytics

Estimate. Approve. Invoice.

Send branded estimates, get quick approvals, and convert jobs into invoices—all in one smooth workflow.

Successful junk removal pricing combines accurate cost calculation, market awareness, and customer value delivery. The strategies and tools in this guide help you quote profitable jobs while building a sustainable, growing business that serves customers effectively.

Transform your junk removal business with professional tools that simplify pricing, improve efficiency, and protect profit margins while delivering exceptional customer service.

Most junk removal companies set a minimum charge of $100-$150 per job. This covers the basic cost of dispatching a truck and crew, even for a single small item. Some companies in high-cost metro areas set minimums at $150-$350. Never price a job below your minimum; it’s not worth the truck deployment, fuel, and labor time for anything less.

Per-item pricing works by assigning a fixed rate to common items based on size, weight, and disposal difficulty. For example: a couch runs $75-$150, a refrigerator $100-$250 (Freon removal adds cost), and a mattress $75-$150. Companies typically have a rate card for the 15-20 most common items they haul. For mixed loads, most switch to volume-based pricing (by truck load fraction) since it’s simpler to estimate and quote.

It depends on the job. Dumpster rentals ($200-$800 for a 20-yard container, 3-7 day rental) are cheaper for large, ongoing projects where you’re loading the dumpster yourself, like a renovation or garage cleanout over several days. Junk removal services ($100-$800 per truck load) are better for one-time pickups where you want the work done for you. For a single truck load of junk, a removal service is often the same price or cheaper than a dumpster rental once you factor in your own labor time.

Volume-based pricing (by truck load) is the industry standard; about 70% of junk removal companies use it. It’s easier for customers to understand (“half a truck load”) and faster to estimate on-site. Use weight-based pricing only for heavy materials like construction debris, concrete, or dirt, where a small volume can weigh significantly more. Many successful companies use a hybrid approach: volume-based as the default, with weight surcharges for dense materials.

A healthy profit margin for junk removal is 30-50% on direct job costs, translating to roughly 15-40% net profit after overhead. New businesses should target at least 30% gross margin to cover unexpected costs and build reserves. Established companies with efficient routes and negotiated disposal rates often achieve 40-50% gross margins. If your margins are below 25%, review your pricing; you’re likely undercharging or not accounting for all costs.

Couch removal typically costs $75-$150 for a standard sofa. Sectional sofas run $100-$200 due to their larger size and weight. Sleeper sofas with mattress mechanisms are at the higher end ($125-$200) because of the extra weight. Add $25-$50 if the couch needs to come down stairs or through a difficult access point. Most companies include this in their minimum charge since a single couch fits easily in a 1/4 truck load.

Yes. Heavy items cost more to handle due to increased labor time, potential injury risk, equipment needs, and higher disposal fees (landfills often charge by weight). Apply a weight surcharge of $25-$100 on top of your standard pricing for items like concrete, safes, pianos, hot tubs, and exercise equipment. This is standard practice; customers understand that a 500-lb safe costs more to remove than a 50-lb desk. Be transparent about weight surcharges in your quotes to avoid disputes.