Pipe Volume Calculator

Calculate the volume of a pipe based on inner diameter and length

Calculation Results

How to use:

- Enter the inner diameter of the pipe

- Enter the length of the pipe

- Select appropriate units for each measurement

- Click "Calculate Volume"

What is Pipe Volume?

Pipe volume refers to the internal capacity of a cylindrical pipe, the total amount of liquid it can hold based on its inner diameter and length. This measurement is typically expressed in liters, cubic inches, or cubic meters, depending on the unit system in use.

To calculate this, the standard formula for the volume of a cylinder is applied:

V=π×r2×L

- V is the volume

- r is the inner radius (half of the inner diameter)

- L is the pipe length

- π (pi) is 3.1416

This formula calculates the interior volume of a cylindrical pipe. It’s widely used in the plumbing industry, irrigation systems, HVAC design, and fluid transport to calculate how much water or other fluid can flow through or be stored inside the pipe.

Knowing your pipe dimensions and using a reliable pipe volume calculator helps ensure accurate results, saving time and reducing errors in real-world projects.

For plumbing professionals, this calculation is essential when creating accurate project estimates using our plumbing estimate template.

How to calculate pipe volume (Example)

Let’s say you have a pipe with:

- Inner diameter = 10 cm

- Length = 200 cm

Step 1: Convert diameter to radius:

10/2 = 5 cm

Step 2: Apply the pipe volume formula:

π×(52)×200 = 3.1416×25×200 = 15,708cm3

Step 3: Convert to liters (1,000 cm³ = 1 liter):

15,708÷1000 = 15.71liters

So, the total pipe volume is approximately 15.71 liters. This tells you how much liquid the pipe can hold, whether it’s water, coolant, or other fluids.

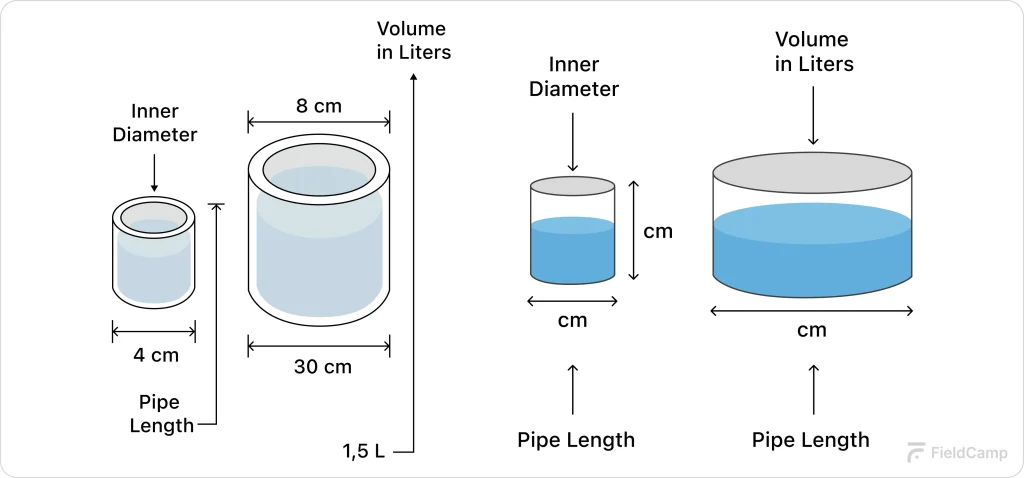

Visual Guide: How the Volume Fills the Pipe

Understanding how volume fills a pipe becomes easier when you visualize the relationship between pipe dimensions and the space inside. This guide helps you see how changes in pipe length and diameter directly impact the interior volume and fluid capacity.

A longer pipe increases total capacity linearly, while a larger diameter increases volume exponentially due to the squared radius in the formula.

Here’s what happens:

Longer Pipe = More Volume

The more length you add, the more space the liquid fills, ideal when extending an irrigation system or planning for underground plumbing.

Larger Diameter = Much More Volume

Even small increases in pipe diameter can drastically increase the volume of fluid the pipe can hold. Doubling the diameter increases the volume by four times (since volume ∝ is radius²).

Consider these scenarios:

- Determine how many liters of water your garden pond piping will hold.

- Calculate how much fluid you need to fill an industrial pipeline.

- Estimate how pressure may change based on filled volume for HVAC or chemical applications.

Common Pipe Volume Examples

To help you better understand how fluid capacity varies based on pipe size and distance, we’ve listed practical examples often used in residential, landscaping, and light industrial settings.

These estimates are useful when you’re planning to fill a pipeline, assess water flow, or calculate liquid needs for projects like irrigation or system design.

Instead of manually working through the math every time, you can refer to this chart for a quick look at typical volume values based on standard dimensions.

Quick Reference Table

| Pipe Size (inches) | Length (ft) | Volume (liters) |

| 2″ | 10 | 6.17 |

| 4″ | 20 | 49.44 |

| 6″ | 25 | 138.9 |

Note: Values are rounded for ease of planning. These results assume full pipe fill and no obstructions.

When to use this:

- Estimating how much water is required to fully charge a system

- Planning water supply for landscaping or agriculture

- Calculating tank fill rates based on pipe-fed systems

- Understanding how pipe size impacts refill time or drainage

Pro Tip: Small increases in diameter lead to large increases in volume. Use this table to avoid underestimating how much liquid mass or water capacity you’ll need to account for in your system.

Real-World Use Cases

The volume of a pipe is a practical measurement used across industries where precise fluid handling, system design, and operational efficiency are critical.

Below are real-world scenarios where calculating the internal pipe capacity can make or break the success of a project.

Plumbing projects

In plumbing, accurately calculating pipe volume helps professionals estimate how much liquid is needed to fill, flush, or maintain a system. Whether you’re winterizing a building and need to add the right amount of antifreeze or applying a chemical drain cleaner, accurate volume matters. Knowing the internal capacity ensures you’re not overusing materials or causing potential damage. It also aids in pressure testing by predicting fill levels before applying force.

Irrigation planning

For landscapers and agricultural engineers, pipe volume directly impacts how efficiently water is distributed across zones. By understanding how many liters each pipe section can hold, you can:

- Determine how long it will take to fill or drain a segment.

- Prevent pressure drops by sizing pipes correctly.

- Optimize water delivery timing based on distance and diameter.

This leads to healthier crops, reduced water waste, and better control over system performance, especially in gravity-fed or pump-controlled irrigation networks.

HVAC systems

In HVAC installations, piping carries refrigerants, chilled water, or glycol mixtures throughout the system. Misjudging how much liquid the pipes can hold can result in:

- Underfilling, which causes inefficient cooling or heating

- Overfilling, which may lead to system pressure spikes or damage

By using a pipe volume calculator, technicians can charge systems more accurately, estimate coolant refill volumes during maintenance, and ensure regulatory compliance in systems where refrigerant tracking is mandatory.

Oil, fuel, and industrial applications

In oil refineries, chemical plants, and fuel transport networks, calculating the internal volume of pipes is critical for:

- Managing how much fluid is in transit

- Avoiding overfilling storage tanks at endpoints

- Ensuring safety protocols during line flushing or purging

This becomes especially important when working with hazardous fluids, where precise control over volume reduces environmental risks and cost. Engineers and facility managers often use volume data to integrate mass flow calculations, fluid density analysis, and transport timing.

Volume of Pipe Calculator in Gallons

While this calculator gives you results in liters, many professionals often work with gallons. To make planning easier, you can easily convert your result from liters to gallons using a simple conversion factor.

Quick conversion formula:

1 liter = 0.264172 gallons (US)

| Liters | Gallons |

| 10 | 2.64 |

| 50 | 13.21 |

| 100 | 26.42 |

| 200 | 52.83 |

This is especially helpful when working with:

- U.S.-based plumbing or construction projects

- Tank capacities and fluid storage requirements are measured in gallons

- Estimating how much water, coolant, or fuel is needed for a job

Instead of doing the math manually, you can use the conversion chart or multiply your result by 0.264172 to get a precise gallon equivalent.

Example of How to Calculate Pipe Volume

Here’s a step-by-step example to show how pipe volume is calculated using the standard formula.

This helps you understand how input values like pipe diameter and length translate into actual fluid capacity:

You have a PVC pipe with:

- Inner diameter: 10 cm

- Length: 200 cm

Step 1: Convert the diameter to a radius

Radius = 10 cm ÷ 2 = 5 cm

Step 2: Apply the pipe volume formula

Volume = π×r2L = 3.1416×(5)2×200 = 3.1416×25×200 = 15,708cm3

Step 3: Convert cubic centimeters to liters

15,708÷1,000 = 15.71 liters

This pipe holds approximately 15.71 liters of fluid, whether it’s water, coolant, or any other liquid used in your system.

Using a dedicated pipe volume calculator simplifies this process, giving you fast and accurate results in just a few clicks without complex conversions or formula handling required.

Advanced Pipe Volume Calculator Features for Pro Users

While basic pipe volume calculations are helpful for everyday tasks, certain use cases demand greater precision. For engineers, contractors, or technical planners, these advanced options ensure the results align with real-world applications where every unit of fluid counts.

Calculate pipe volume by wall thickness

If you’re working with materials like PVC, steel, or copper, accounting for pipe wall thickness is essential. The default formula assumes full internal space, but real pipes have a thickness that reduces usable volume.

By inputting the outer diameter and wall thickness, you can calculate the true inner volume, especially important for:

- Material estimation

- Hydraulic modeling

- Piping systems in mechanical or civil engineering

This adjustment gives you a more accurate result for fluid-only capacity.

Convert volume to weight

Need to know the mass of the liquid inside the pipe? Once you’ve calculated volume, you can select a fluid type (e.g., water, oil, diesel) to estimate its weight using the average liquid density.

For example:

- 1 liter of water weighs ~1 kg

- 1 liter of diesel weighs ~0.85 kg

This is extremely useful for:

- Structural load calculations

- Transport weight estimation

- Pump and flow rate analysis

Batch volume calculator

Handling multiple pipe segments across a system or layout?

Instead of calculating them one by one, batch mode lets you enter:

- Different pipe sizes

- Varying lengths

The tool then returns the total liquid capacity across the system, perfect for large plumbing projects, irrigation designs, or industrial piping layouts.

Pipe Volume Conversion Chart

Sometimes your pipe dimensions may be in inches or cubic feet, but your project requires results in liters or gallons.

This conversion chart makes switching between units fast and easy.

Convert Between Units

| From | To | Formula |

| Gallons | Liters | × 3.785 |

| Cubic Feet | Gallons | × 7.48 |

| Liters | Cubic Meters | ÷ 1000 |

| Cubic Inches | Liters | ÷ 61.024 |

| Liters | Cubic Inches | × 61.024 |

These conversions help when sharing specs across regions or working with mixed unit systems in plumbing, HVAC, or industrial installations.

Free Pipe Calculators and Planning Tools for Smarter Estimates

Help your visitors save time, plan smarter, and estimate better by offering them related free tools that complement the pipe volume calculator.

Each tool addresses a specific stage in project planning, from calculating pipe length to managing project costs.

Pipe length estimator

- Helps users determine how much piping they need based on coverage area or system layout.

- Perfect for planning irrigation systems or indoor plumbing installations.

Fluid weight calculator

- Converts liquid volume (in liters) into weight, based on fluid type and density.

- Ideal for estimating load, transport limits, or structural pressure.

Markup & profit margin calculator

- Easily calculate how much to charge for labor and material markup.

- Useful for contractors, plumbers, and service providers quoting jobs.

Handyman or plumbing business plan template

- Downloadable, editable template to help users plan their business goals, costs, and services.

- Helps bridge the gap between tools and business strategy.

Use our free, editable handyman business plan template to map out your services, pricing, and goals. Whether you’re launching a plumbing business or expanding your team, this resource helps turn your expertise into a scalable, service-ready plan.

FieldCamp Job Estimator Software

- Free online software to manage job estimates, clients, and materials.

- Syncs well with the usage of calculators for pipe volume, length, and cost planning.

Frequently Asked Questions

What affects the amount of liquid a pipe can hold?

Several factors affect the total pipe volume, or how much liquid a pipe can hold. The two most critical elements are the inner diameter and the length of the pipe. A larger diameter increases the internal space exponentially, while a longer pipe linearly adds volume. Additionally, factors like pipe wall thickness, internal obstructions, and pipe slope can influence how much usable space is available inside. For systems like plumbing, irrigation, or fuel transfer, accurately measuring these dimensions ensures efficient fluid handling and system performance.

Why is it important to know the pipe’s internal volume?

Knowing a pipe’s internal volume is essential for ensuring efficient liquid management in many systems. For example, in plumbing projects, it helps prevent overflows and ensures the right amount of cleaner or antifreeze is used. Agricultural irrigation allows accurate water delivery planning across different zones. Industrial applications also rely on pipe volume data to manage liquid mass, flow rates, and system safety. Using a pipe calculator ensures you’re not relying on estimates and can plan material usage and capacity with confidence.

Can I use this pipe volume calculator for other fluids besides water?

Yes, the pipe volume calculator works for any fluid, not just water. Once you know the volume in liters or cubic units, you can apply the fluid density to estimate the weight or behavior of other liquids such as oil, diesel, coolant, or chemical solutions. This is especially useful for professionals working in HVAC, chemical transport, or fuel systems, where the type of fluid impacts safety standards, pressure ratings, and system performance.

What’s the difference between inner and outer diameter in pipe measurements?

The inner diameter of a pipe determines how much liquid it can hold — it defines the actual interior volume. The outer diameter includes the pipe’s wall thickness and is important when considering installation clearances or material costs. For accurate pipe volume calculations, always use the inner diameter, as the space inside the pipe is what affects how much fluid it can contain. Tools and fittings are also often sized based on inner diameter to ensure compatibility with the system’s fluid capacity.

Do I need a pipe volume calculator for small residential jobs?

Even for smaller residential tasks like installing an irrigation line, setting up a garden water system, or replacing plumbing sections, a pipe volume calculator can be incredibly helpful. It ensures you know exactly how much water or fluid is needed to fill the pipe, helps estimate drainage or flushing volumes, and avoids trial-and-error mistakes. It’s especially useful when working with expensive or limited fluids, or when planning projects that require accurate fluid measurement and time-saving planning.

How many gallons per foot of pipe?

The number of gallons per foot depends on the inner diameter of the pipe. For example:

How to calculate the amount of liquid in a pipe?

To find out how much liquid a pipe can hold, enter the inner diameter and length into a pipe volume calculator. The tool calculates the interior volume, which represents how much liquid can fill the pipe. For more accuracy, you can also factor in the type of fluid by applying its density to calculate weight or mass, especially for non-water substances like oil, fuel, or coolants.

Are there any apps for calculating pipe volume?

Yes, there are several web and mobile apps designed specifically for pipe volume calculations. FieldCamp offers a free, browser-based pipe volume calculator that’s easy to use and gives instant results in liters. These tools eliminate the need for manual conversions and are especially helpful for many industries.