Overview

Running out of parts in the middle of a job doesn’t just delay completion – it costs you money, frustrates customers, and damages your professional reputation. Yet 73% of field service companies still manage inventory manually, leading to frequent stockouts, overstocking expensive parts, and technicians making emergency supply runs that kill profitability.

The problem extends beyond just knowing what you have in stock. Manual inventory management creates a cascade of inefficiencies: technicians hoarding parts on trucks, purchasing ordering too much or too little, no visibility into which parts are profitable vs. loss leaders, and no systematic way to optimize inventory investment across multiple locations and vehicles.

Our inventory and parts management automation solves these challenges by providing real-time visibility into every part across your entire operation – from warehouse shelves to technician trucks. The system automatically tracks usage, predicts demand, manages reorder points, and even handles vendor relationships to ensure you always have the right parts available without tying up excessive capital in inventory.

Whether you’re an HVAC contractor managing seasonal parts demand, a plumbing business tracking thousands of fittings and fixtures, or a multi-trade company coordinating inventory across different service lines, this automation ensures optimal parts availability while minimizing inventory costs and eliminating manual tracking overhead.

Implementation Results

Field service companies using inventory automation see significant improvements:

84%

Stockout Reduction

92%

Manual Counting Time reduction

31%

Inventory Carrying Costs lower

47%

Parts Profitability improvement

Results based on FieldCamp customer data from 160+ field service businesses over 22 months

Key Benefits

- Eliminate Costly Stockouts Never send technicians to jobs without the right parts again. Real-time tracking and predictive reordering ensure critical parts are always available when needed, eliminating job delays and customer dissatisfaction.

- Automate Manual Processes Stop spending hours counting parts and updating spreadsheets. Automated tracking and reporting eliminate 92% of manual inventory management tasks, freeing your team to focus on revenue-generating activities.

- Maximize Parts Profitability Track parts usage vs. billing to ensure every part generates appropriate profit margins. Identify opportunities to increase markup, eliminate loss leaders, and optimize pricing strategies based on actual usage data.

- Scale Operations Confidently Handle business growth without proportional increases in inventory management overhead. The automation scales effortlessly whether you manage 100 or 10,000 SKUs across single or multiple locations.

Key Features

- Real-Time Multi-Location Tracking Monitor inventory levels across warehouse, trucks, and job sites in real-time. The system provides complete visibility into where every part is located and automatically updates quantities as parts are used or restocked.

- Mobile Truck Inventory Technicians can instantly update truck inventory using mobile devices, scanning parts as they’re used on jobs. This real-time updating ensures accurate system-wide inventory counts without manual processes.

- Cost and Profitability Analytics Comprehensive reporting shows parts usage patterns, profitability by SKU, vendor performance metrics, and optimization opportunities. This data drives strategic inventory decisions and improves overall profitability.

How Our Inventory Automation Works

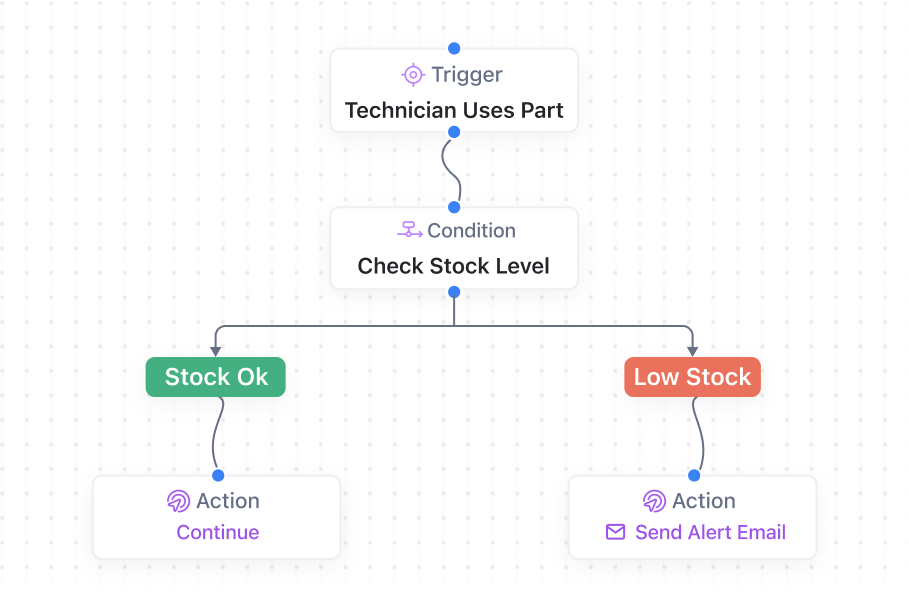

Real-Time Usage Tracking Every time a technician uses a part on a job, the mobile app automatically updates inventory levels across all locations. The system tracks which parts were used, where they came from (truck vs. warehouse), and what they were billed at.

Intelligent Reorder Point Management The system continuously analyzes usage patterns, seasonal trends, and vendor lead times to maintain optimal reorder points for every SKU. These thresholds automatically adjust based on demand changes and business growth.

Automated Purchase Order Generation When inventory levels hit reorder points, the system automatically generates purchase orders with approved vendors. Orders include optimal quantities based on usage rates, vendor minimums, and economic order quantities.

Cost and Billing Analysis Every part usage is tracked against billing to ensure appropriate markups and identify opportunities for pricing optimization. The system flags discrepancies and provides profitability analysis by part, job, and customer.

Exception Reporting and Alerts Automated alerts notify managers of stockouts, overstock situations, vendor delays, price variances, and profitability issues. This proactive notification ensures rapid response to inventory challenges.

How to Setup the Template

Step 1: Import Current Inventory Upload your existing parts catalog with current quantities, locations, costs, and vendor information. The system will establish baseline inventory levels and begin tracking from this starting point.

Step 2: Configure Reorder Parameters Set reorder points, maximum stock levels, and preferred order quantities for each SKU based on your usage patterns and storage capacity. The system will refine these automatically based on actual usage data.

Step 3: Deploy Mobile Tracking Train technicians on mobile inventory management including scanning parts usage, reporting stockouts, and updating truck inventory levels. This mobile integration is critical for real-time accuracy.

Step 4: Configure Alerts and Reports Set up automated alerts for low stock, overstock, vendor delays, and profitability issues. Configure regular reports for inventory analysis, vendor performance, and cost optimization opportunities.

Setup typically takes 5-6 hours with FieldCamp’s dedicated inventory specialist ensuring all SKUs are properly configured and tracking accurately from day one of implementation.

Who Should Use This Template

HVAC and Plumbing Contractors Companies with thousands of parts and seasonal demand variations benefit enormously from automated tracking and predictive reordering. The system ensures availability during peak seasons while minimizing off-season carrying costs.

Multi-Trade Service Companies Businesses managing diverse inventories across different service lines need systematic tracking to optimize investment and ensure cross-utilization of compatible parts between trades.

High-Volume Parts Users Companies using hundreds of parts monthly need automated systems to prevent stockouts and optimize purchasing. Manual tracking becomes impossible at scale without sacrificing accuracy.

Multi-Location Operations Businesses with multiple warehouses, service centers, or large truck fleets need centralized visibility and coordinated inventory management to optimize parts allocation and reduce redundant stocking.

Growing Service Businesses Companies scaling operations need systematic inventory management to support growth without proportional increases in inventory management overhead or working capital requirements.

Frequently Asked Questions

How does the system handle parts with long lead times or seasonal demand?

The system analyzes historical usage patterns and adjusts reorder points based on lead times and seasonal variations. It can automatically increase stock levels before peak seasons and reduce them during slower periods.

Can technicians update inventory from their trucks?

Yes, the mobile app allows technicians to scan parts as they use them, report stockouts, and update truck inventory levels in real-time. This ensures system-wide accuracy without requiring office visits.

How does this integrate with our accounting system?

The system integrates with QuickBooks and other accounting platforms to automatically update inventory values, cost of goods sold, and vendor payables. This eliminates duplicate data entry and ensures financial accuracy.

What if we have multiple vendors for the same parts?

The system can manage multiple vendors per part with different pricing, lead times, and minimum orders. It automatically selects optimal vendors based on availability, pricing, and performance criteria you define.

Can we track parts profitability by job or customer?

Absolutely. The system tracks parts costs vs. billing amounts and provides detailed profitability analysis by part, job, customer, and time period. This helps optimize pricing and identify profit improvement opportunities.

Template Details

Category

Operations & Inventory Management

Use Case

All field service businesses with significant parts inventory

Requirements

- FieldCamp inventory management module

- Mobile devices for technicians with scanning capability

- Vendor integration setup for major suppliers

- Accounting system integration (QuickBooks recommended)

- Warehouse and truck inventory organization

- Parts catalog with proper SKU classification