What Is Multi-Day Job Scheduling? A Field Service Guide

January 24, 2026 - 17 min read

January 24, 2026 - 17 min read

Table of Contents

| TL;DR: Multi-day job scheduling is the process of planning field service work that spans more than one calendar day, installations, renovations, large-scale repairs, or any project too complex for a single visit. It requires technician continuity, coordinated resources, and proactive customer communication that single-day scheduling doesn’t demand. |

You know that moment in Jenga when the tower starts swaying?

Early in the game, you can pull almost any block. No problem. But a few rounds in, everything changes. Every block you touch affects the blocks around it. One wrong move doesn’t just remove a piece; it brings the whole thing crashing down.

That’s what multi-day job scheduling feels like.

When you’re managing a three-day installation or a week-long retrofit, every day stacks on the one before. Your crew assignments, material deliveries, and customer commitments are all connected.

One block shifts, a technician calls in sick, a site isn’t ready, materials arrive late, and suddenly your entire week is collapsing, not just one appointment.

Research from the Project Management Institute shows that poor scheduling and miscommunication contribute to nearly 30% of project failures, and the stakes multiply when work spans multiple days.

Single-day jobs don’t work like this. They’re independent blocks. Move one, the others don’t care.

But multi-day field service projects? That’s a tower where every piece leans on every other piece. And the scheduling system that worked fine for single-day calls will absolutely break under this weight.

This guide breaks down what multi-day job scheduling actually means, why it’s harder than regular dispatching, and what it takes to keep your tower standing when things inevitably shift.

Because they will shift. They always do.

KEY HIGHLIGHTS

Multi-Day Job Scheduling

Multi-day job scheduling is the process of planning and coordinating field service work that spans more than one calendar day. Instead of dispatching a technician for a few hours and moving on, you’re committing resources, often the same crew, across multiple shifts until the project is complete.

Think about what this actually looks like in the field:

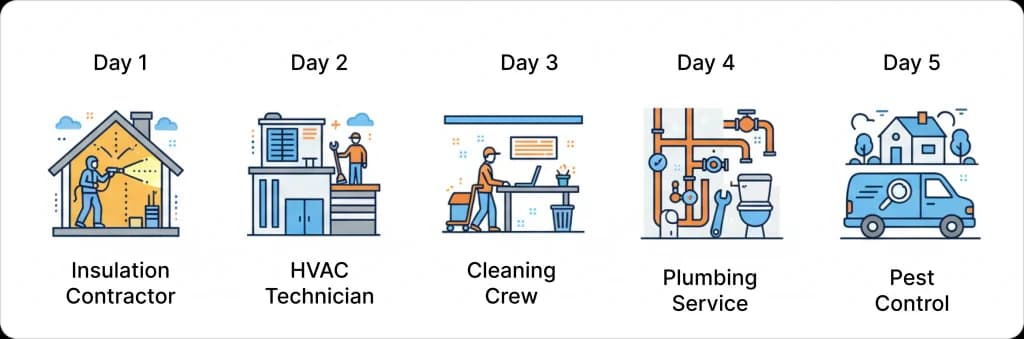

An insulation contractor sends a removal crew on Monday to strip old material from an attic. Tuesday, the spray foam team arrives to install new insulation. Both days need to be coordinated as one project, not two separate jobs.

An HVAC company schedules a commercial system replacement. The work takes four days: equipment delivery, old system removal, new installation, and testing. The same lead technician needs to be there throughout.

A plumbing contractor takes on a whole-house repipe. Water gets shut off each morning and restored each evening. The crew works room by room across three days while the homeowner adjusts their routine around your schedule.

These aren’t just “long jobs.” They’re projects with dependencies, milestones, and customer touchpoints that require a fundamentally different scheduling approach than quick service calls.

The core challenge is coordination. You’re not just assigning a technician to a time slot; you’re orchestrating a sequence of events across days, often involving multiple people, staged materials, and ongoing customer communication.

Get this wrong, and you’re dealing with missed handoffs, frustrated customers, and projects that run over budget.

Get it right, and you unlock the ability to take on higher-value work that single-day-focused competitors can’t handle.

These are the capabilities of multi-day scheduling. Let’s understand how it differs from single-day scheduling.

Prefer listening over reading? Check out our podcast!

The difference isn’t just duration. Multi-day jobs change how you schedule, communicate, and allocate resources.

| Factor | Single-Day Jobs | Multi-Day Jobs |

| Duration | A few hours | Days to weeks |

| Technician assignment | Any available tech with the right skills | Same crew throughout (continuity matters) |

| Customer communication | One confirmation, one completion update | Daily updates, ongoing coordination |

| Resource planning | Grab parts from the truck | Staged materials, overnight equipment, mid-project deliveries |

| Scheduling complexity | Low, slot it into an open time block | High, block multiple days, manage dependencies |

| Impact of delays | Reschedule one appointment | Cascade effect across entire project timeline |

| Job records | Single entry | Unified record with daily breakdowns |

When you treat multi-day work like a series of single-day appointments, things fall apart. Records get fragmented. Context gets lost between days. Dispatchers lose visibility into the full project picture.

The distinction matters because your scheduling approach and the tools you use need to match the complexity of the work.

If your business only handles quick service calls, single-day scheduling is fine. But most growing field service operations eventually take on bigger projects. And bigger projects mean bigger revenue.

According to the U.S. Bureau of Labor Statistics, employment in construction and extraction occupations is projected to grow faster than average through 2034, with about 649,300 openings annually. Much of this growth comes from installation-heavy sectors like electrical contracting (projected 6.6% growth) and renewable energy infrastructure.

These aren’t quick service calls; they’re multi-day installations, system replacements, and large-scale repairs.

Here’s why getting multi-day scheduling right matters:

A $500 service call is good. A $7,500 insulation project is better. But you can only capture that revenue if you can actually schedule and execute the work without chaos.

When multi-day jobs run over schedule, you’re not just delaying one customer; you’re pushing back everything else on your calendar. Crews sit idle waiting for delayed materials. Customers get frustrated with changing timelines. Your dispatch team scrambles to reorganize the week.

Homeowners adjusting their lives around a three-day project have higher expectations than someone waiting for a two-hour repair. They want to know exactly when you’re arriving, what’s happening each day, and when you’ll be finished. Meet those expectations, and you earn referrals. Miss them, and you earn bad reviews.

Field service businesses that master multi-day scheduling can confidently bid on larger projects. Those still relying on manual methods avoid complex work or take it on and struggle. The gap between these two groups widens as the industry grows.

Multi-day scheduling applies across field service industries, anywhere work is too complex, too large, or too involved to complete in a single visit.

Electrical contractors running panel upgrades, roofers replacing a full roof, restoration companies handling water damage, landscapers installing irrigation systems, the list goes on.

Here’s how multi-day work looks in practice across several common industries. The specific challenges differ, but the underlying scheduling requirements are similar.

Insulation work frequently spans multiple days, especially for larger residential retrofits or commercial projects.

A typical scenario: the project quote comes in around $8,000. That’s too much work for a single day. So you schedule a removal crew for day one, stripping out old fiberglass or cellulose. Day two, your spray foam team arrives to install new material. Both crews need access to the same site, but they can’t overlap.

If removal runs late, installation gets pushed.

What makes insulation scheduling tricky:

The contractors who handle this well treat multi-day insulation work as a single unified project. They assign a project lead who owns the full timeline. They build buffer time between crews.

And they keep the customer informed at every transition.

Commercial HVAC installations are rarely one-day jobs. A full system replacement for an office building or retail space can take a week or more.

Even residential work gets complicated. A complete system swap, removing the old furnace and AC, installing new equipment, running new lines, testing everything, often spans two to three days. And if you’re also handling ductwork modifications, add another day.

What makes HVAC scheduling tricky:

The best HVAC operations protect their multi-day installation slots. They don’t let emergency calls pull technicians off scheduled projects mid-job.

They assign their most experienced techs to complex installs and keep them there until the work is done.

Deep cleaning contracts don’t happen in a single shift. A thorough cleaning of a 50,000 square foot office building might take three days, one floor per day, with specialized equipment moving through the space systematically.

Post-construction cleaning is even more involved. After a renovation or new build, cleaning crews work room by room, often returning multiple times as other trades finish their punch lists.

What makes commercial cleaning scheduling tricky:

Smart cleaning companies create project templates for common multi-day scenarios. A “full building deep clean” template might include day-by-day task breakdowns, crew assignments, and equipment checklists, so dispatch isn’t reinventing the wheel every time.

Repiping is the classic multi-day plumbing job. Replacing all the water supply lines in a home takes two to five days, depending on the house size and pipe accessibility.

The scheduling challenge goes beyond just blocking time. You need to coordinate water shutoffs with the homeowner’s schedule. You need to sequence work so the house has water each evening. You might need inspections between phases before you can close up walls.

What makes plumbing scheduling tricky:

Plumbing contractors who excel at multi-day work communicate relentlessly. They tell homeowners exactly what to expect each day. They send text updates when crews are arriving and leaving. They make the disruption as predictable as possible.

Individual treatments are quick. But pest control businesses run what are essentially ongoing multi-day operations through their recurring service routes.

Think about a technician’s week: Monday covers the north side of town, Tuesday the east side, Wednesday commercial accounts, and so on. This route-based scheduling shares DNA with multi-day project work; you’re coordinating resources across an extended timeline, just distributed across many customers instead of one.

What makes pest control scheduling tricky:

The pest control operators who run efficiently treat their weekly route as an integrated system.

They don’t just schedule day by day; they optimize across the full week using multi-stop route planning, leaving buffer capacity for urgent requests without blowing up their entire route.

Even experienced operations directors hit the same walls when managing extended projects.

When jobs span multiple days, you want the same person handling the work from start to finish. They know the site. They remember what was done yesterday. They don’t need to spend the first hour figuring out what’s going on.

But continuity is hard to maintain when your scheduling system optimizes for “efficiency” by reassigning available techs wherever gaps appear.

Suddenly, your lead installer gets pulled for an emergency call, and now someone new is showing up to continue a project they know nothing about.

Multi-day projects have dependencies. Day two can’t start until day one finishes. So when day one runs long, because of weather, or access issues, or unexpected complications, everything downstream shifts.

The problem compounds when you’re running multiple multi-day projects simultaneously. A delay on Project A might bump the crew that was supposed to start Project B tomorrow.

Now you’re calling customers, rearranging schedules, and apologizing for timelines you confidently promised.

A customer waiting for a two-hour repair gets one text: “Tech is on the way.” A customer living through a four-day project needs a fundamentally different communication experience.

They want to know: What’s happening today? What time are you arriving? What should I do to prepare? How much progress did you make? What’s the plan for tomorrow?

Most field service businesses aren’t set up to deliver this level of ongoing communication without drowning their office staff.

You can’t just grab parts from the truck for multi-day work. Materials need to be ordered ahead, delivered to the site, and sometimes stored overnight. Equipment might need to stay on-site between days, which raises security and liability questions.

When staging isn’t planned properly, technicians show up ready to work and discover the materials they need didn’t arrive.

Now, day two is wasted, and the whole project timeline is extended.

Whiteboards, spreadsheets, and basic calendar apps work fine when your jobs are simple and your team is small. Multi-day projects break these systems.

You need to see resource allocation across multiple days at once. You need to prevent dispatchers from accidentally booking over protected project time.

You need historical data on how long similar projects actually took, so your estimates improve. Manual methods can’t deliver this, and the bigger you grow, the more painful the gaps become.

If multi-day work is becoming a bigger part of your business, your scheduling tools need to keep up.

Here’s what actually matters.

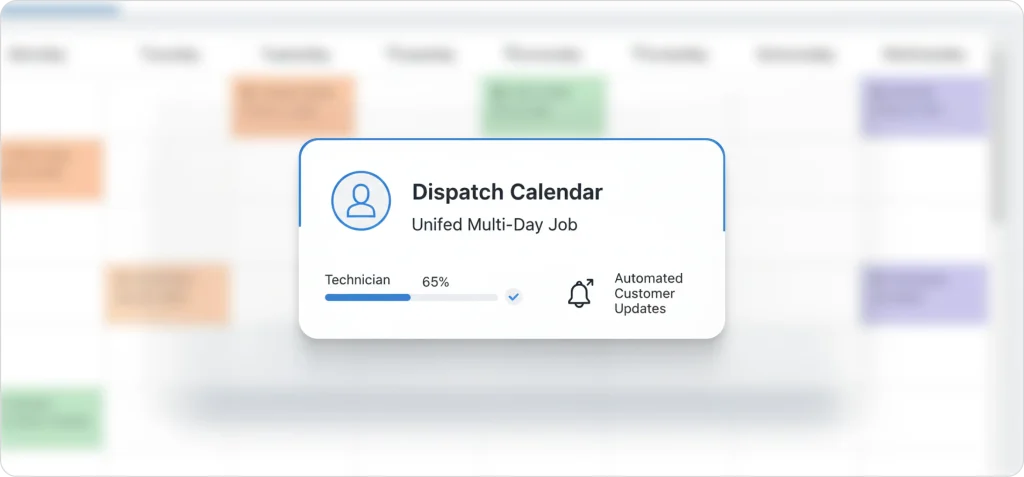

You need to schedule multi-day work as one project, not as a series of disconnected daily appointments. A unified record shows the full timeline, tracks progress across days, and keeps all job notes, photos, and communications in one place.

When jobs get fragmented into separate appointments, context gets lost. Technicians don’t see the full picture. Dispatchers can’t tell if a project is on track or falling behind. Customers get confused by multiple confirmation messages that don’t connect.

The same technician or crew should handle the entire project whenever possible. Your scheduling software needs to respect that.

Look for the ability to lock assignments, so when your route optimization runs, it doesn’t pull your lead installer off a three-day project to fill a gap elsewhere. The system should treat multi-day assignments as protected commitments, not movable pieces.

You shouldn’t have to chase technicians for updates on multi-day work. The software should make it easy to log daily progress, note issues, and update completion percentages.

This visibility matters for dispatchers managing multiple projects, for office staff fielding customer calls, and for business owners trying to understand job profitability.

Proactive communication is expected on multi-day work, but it’s time-consuming if done manually. The right software sends automated notifications: arrival confirmations, end-of-day summaries, and schedule reminders for the next day.

This keeps customers informed without burying your team in phone calls and texts.

Delays happen. When they do, you need to see the downstream impact immediately and adjust accordingly.

Good scheduling software doesn’t just show you that day two is delayed; it shows you what that means for the rest of the project, for other scheduled work, and for technician availability. Then it helps you find the best path forward instead of leaving you to untangle the mess manually.

FieldCamp’s AI-powered dispatch was built specifically for the complexity of multi-day work. Unified job records, resource locking, automated progress tracking, and intelligent rescheduling come standard, not as workarounds you have to build yourself.

Explore FieldCamp’s multi-day scheduling capabilities in detail, or see how AI job scheduling works for your operation.

Multi-Day Jobs Don’t Have to Mean Multi-Day Headaches

FieldCamp schedules your crews, tracks progress, and keeps customers updated, so you can focus on the work that pays off.

Multi-day job scheduling is the process of planning field service work that spans more than one calendar day. It involves coordinating technician assignments, resource allocation, and customer communication across an extended timeline, treating the work as a unified project rather than separate daily appointments.

Nearly every field service industry deals with multi-day work at some point. Insulation, HVAC, plumbing, electrical, roofing, commercial cleaning, restoration, landscaping, solar installation, fire protection, and general contracting all regularly handle projects spanning multiple days. If your work involves installations, major repairs, renovations, or large-scale maintenance, you’re dealing with multi-day scheduling.

Single-day jobs are dispatched, completed, and closed within a few hours. Multi-day jobs require sustained commitment across multiple shifts, with the same crew maintaining continuity, materials staged across days, and ongoing customer communication throughout the project.

Multi-day work introduces dependencies; day two can’t start until day one finishes. It requires resource locking to maintain technician continuity. It demands proactive communication across an extended timeline. And delays cascade, affecting not just one appointment but the entire project schedule and potentially other booked work.

Look for unified job records (not fragmented appointments), resource locking (protect assignments from being reassigned), progress tracking across days, automated customer updates, and intelligent rescheduling that shows downstream impacts when timelines shift.

Yes. Even small operations occasionally take on larger projects, such as a full insulation retrofit, a system replacement, a deep cleaning contract. Having the right scheduling approach (and tools) lets you confidently bid on this higher-revenue work instead of avoiding it or struggling through with manual methods.