Spray Foam vs Blown-In vs Batt Insulation: Which Is Best?

February 5, 2026 - 21 min read

February 5, 2026 - 21 min read

Table of Contents

| TL;DR: Spray foam delivers the highest R-value per inch (3.7-6.7) and best air sealing but costs $1.50-$3.50 per square foot. Blown-in insulation (R-2.3-4.3 per inch) balances performance and price at $0.60-$1.50 per square foot. Fiberglass batts are the most affordable option at $0.30-$1.00 per square foot with R-2.9-3.8 per inch. The right choice depends on your home’s age, location, and budget. |

Nearly 90% of US homes are under-insulated, according to the North American Insulation Manufacturers Association. That means most homeowners are paying hundreds of dollars more per year on heating and cooling than they need to.

The insulation industry is projected to reach $78.5 billion by 2030, driven by energy efficiency mandates and rising utility costs.

If you are dealing with drafty rooms, uneven temperatures, or energy bills that keep climbing, upgrading your insulation is one of the highest-ROI home improvements you can make. But the decision between spray foam vs blown-in vs batt insulation trips up even experienced homeowners.

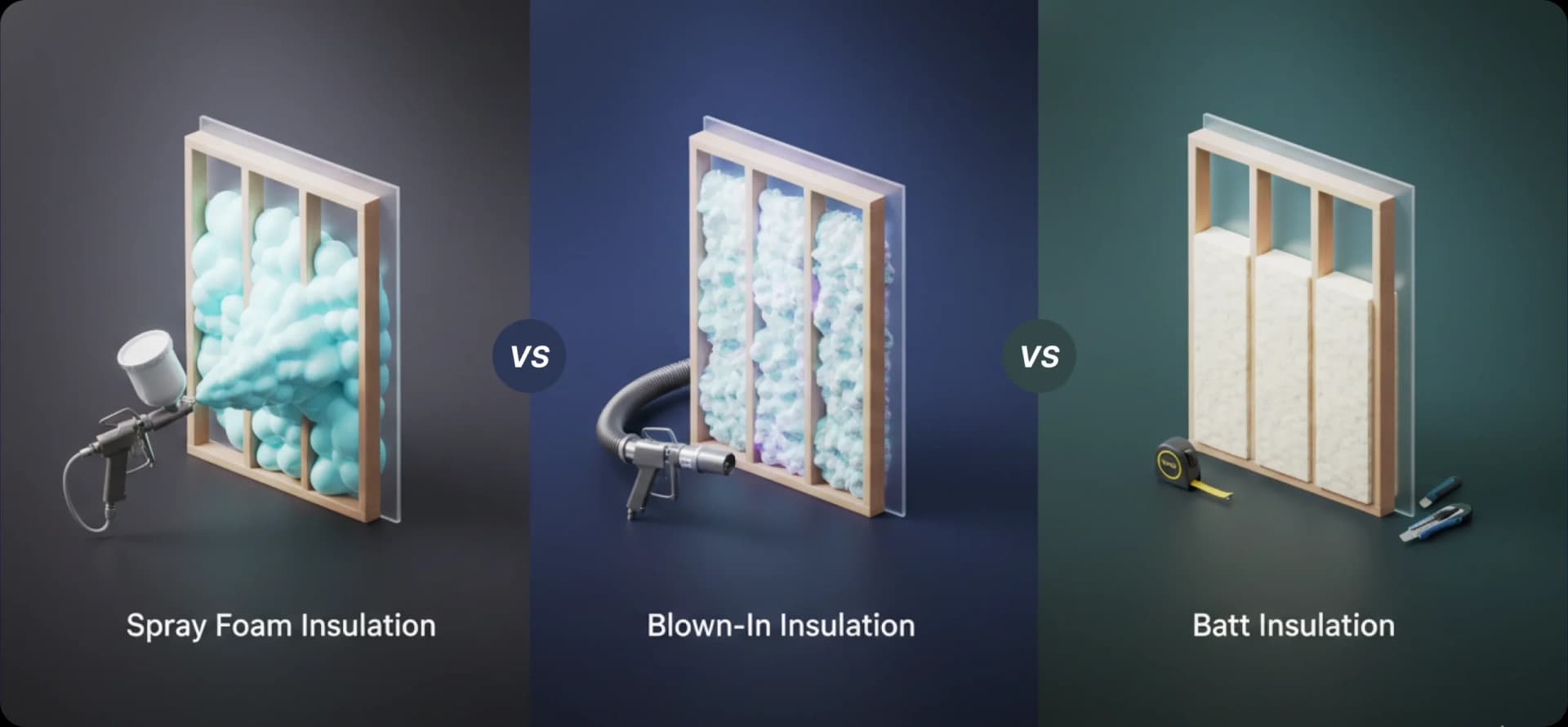

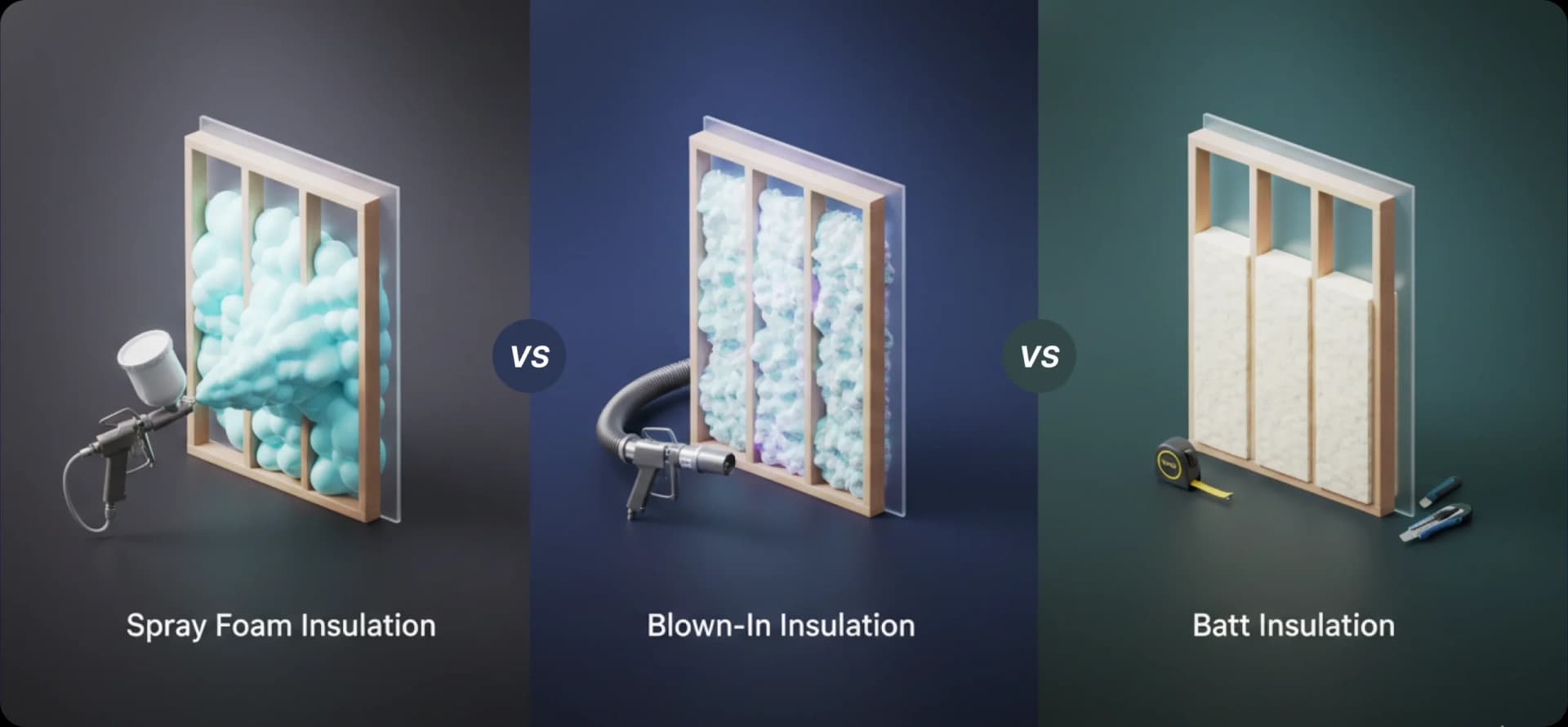

Each type comes with different R-values, costs, installation requirements, and best-use scenarios. Spray foam is the premium choice. Blown-in offers versatility. Batts deliver budget-friendly performance. But “best” depends on whether you are insulating a new build, retrofitting an old attic, or sealing a crawl space.

As the U.S. Department of Energy notes, “The amount of insulation or R-value you’ll need depends on your climate, type of heating and cooling system, and the part of the house you plan to insulate.”This guide breaks down every factor, including R-value performance, upfront and long-term costs, best applications by home area, health and safety considerations, and a decision matrix to help you pick the right insulation type.

Whether you are a homeowner planning a retrofit or an insulation contractor using field service management software to run your business, this comparison covers everything you need.

KEY HIGHLIGHTS

Comparing the Three Insulation Types for US Homeowners

A side-by-side comparison of spray foam, blown-in, and batt insulation shows clear differences in performance, cost, and ideal use cases. Spray foam leads in R-value and air sealing, blown-in excels in retrofit versatility, and batts win on upfront affordability for open framing.

| Feature | Spray Foam | Blown-In | Fiberglass Batt |

| R-value per inch | 3.7-6.7 | 2.3-4.3 | 2.9-3.8 |

| Air sealing ability | Excellent (acts as air barrier) | Moderate (needs separate air sealing) | Low-moderate (depends on installation) |

| Moisture resistance | High (especially closed-cell) | Good (cellulose is treated for moisture) | Good when kept dry |

| Upfront cost per sq ft | $1.50-$3.50 | $0.60-$1.50 | $0.30-$1.00 |

| DIY-friendly | No (requires professional) | Partially (blower rental available) | Yes (most common DIY insulation) |

| Best for | Crawl spaces, rim joists, attics, walls | Attic retrofits, irregular cavities, existing walls | New construction, open joist bays, budget projects |

| Lifespan | 80+ years | 20-30 years | 15-25 years |

| Soundproofing | Good | Excellent (cellulose) | Moderate |

No single insulation type is “best” for every situation. Spray foam is the performance leader. Blown-in is the retrofit champion. Batts are the budget pick. Your home’s age, location, and specific needs determine the right choice.

The three main residential insulation types are spray polyurethane foam (SPF), blown-in loose-fill (cellulose or fiberglass), and fiberglass batt insulation. Each uses different materials, installation methods, and delivers different thermal performance per inch of thickness.

Spray foam insulation is a liquid polyurethane that expands and hardens to seal cracks, gaps, and cavities. It comes in two types.

| Spray Foam Type | R-Value Per Inch | Best Applications | Key Benefits |

| Closed-cell | R-6.0 to R-6.7 | Basements, crawl spaces, exterior walls | Adds structural strength, vapor barrier |

| Open-cell | R-3.5 to R-3.7 | Interior walls, attic rooflines | Excellent soundproofing, lower cost |

Closed-cell spray foam delivers R-6 to R-6.7 per inch. It is rigid, adds structural strength, and acts as a vapor barrier. This makes it ideal for basements, crawl spaces, and exterior walls where moisture control matters.

Open-cell spray foam provides R-3.5 to R-3.7 per inch. It is softer, less expensive, and excels at soundproofing. It works well in interior walls and attic rooflines.

As one industry source puts it: “Spray foam insulation has a higher R-value per inch. This translates to better thermal resistance. Proper air sealing is crucial. Spray foam excels at sealing small cracks and gaps.”

Closed-cell spray foam is the only insulation type that simultaneously insulates, air seals, and blocks moisture. If you are insulating a basement or crawl space, it often eliminates the need for a separate vapor barrier.

Blown-in insulation is loose-fill material pneumatically installed using a blowing machine. The two main materials are cellulose (recycled newspaper treated with fire retardants) and fiberglass.

| Blown-In Type | R-Value Per Inch | Recycled Content | Key Benefits |

| Cellulose | R-3.2 to R-3.8 | Up to 85% | Fire resistant (borate treated), excellent soundproofing |

| Fiberglass | R-2.2 to R-4.3 | 20-30% | Less settling, moisture resistant |

Blown-in insulation fills spaces more thoroughly than batts, especially in attics with irregular joist spacing, around wiring, and in existing wall cavities accessed through small drill holes.

Dense-pack blown-in cellulose is the go-to solution for insulating existing walls without removing drywall. A contractor drills small holes, fills the cavity completely, then patches the holes. Contractors can streamline this process using digital checklists to ensure consistent quality across every job.

Fiberglass batt insulation comes in pre-cut blankets or rolls sized to fit standard stud and joist spacing (16 or 24 inches on center). It delivers R-2.9 to R-3.8 per inch.

Batts are the most widely available and affordable insulation type. They are DIY-friendly for new construction or exposed framing. However, performance depends entirely on installation quality.

“Batt insulation is affordable and relatively easy to install, making it a popular choice for DIY projects,” notes Harpe Development. But gaps, compression, and poor fitting around electrical boxes and pipes can reduce effective R-value by 25% or more.

Warning: Never compress fiberglass batts to fit a thinner cavity. A batt rated R-19 compressed from 6.25 inches to 3.5 inches drops to roughly R-13. Always match batt thickness to cavity depth.

R-value measures thermal resistance. Higher R-value per inch means better insulation performance per unit of thickness. Spray foam leads at R-3.7-6.7 per inch, followed by blown-in at R-2.3-4.3, and batts at R-2.9-3.8. But R-value alone does not tell the full story.

| Insulation Type | R-Value Per Inch | R-Value for 3.5″ Wall | R-Value for 5.5″ Wall |

| Closed-cell spray foam | 6.0-6.7 | R-21 to R-23 | R-33 to R-37 |

| Open-cell spray foam | 3.5-3.7 | R-12 to R-13 | R-19 to R-20 |

| Cellulose blown-in | 3.2-3.8 | R-11 to R-13 | R-18 to R-21 |

| Fiberglass blown-in | 2.2-4.3 | R-8 to R-15 | R-12 to R-24 |

| Fiberglass batts | 2.9-3.8 | R-11 to R-13 | R-19 to R-21 |

R-value ratings assume perfect installation. In reality, air leaks dramatically reduce insulation effectiveness.

A wall insulated with R-13 fiberglass batts but with gaps around outlets, pipes, and top plates might perform like R-9 or worse. The same wall with spray foam at R-13 performs at or above its rated value because foam seals air paths simultaneously.

The U.S. Department of Energy advises: “Before you insulate, you should make sure that your home is properly air sealed.” Air sealing combined with adequate insulation thickness delivers the highest energy savings.

When comparing spray foam vs blown-in vs batt insulation, focus on “effective R-value,” which accounts for real-world air leaks and installation quality. Spray foam’s built-in air sealing gives it an advantage that R-value numbers alone do not show.

The DOE recommends different minimum R-values depending on your US climate zone.

| Climate Zone | Attic | Walls | Floor |

| Zone 1-2 (Southern FL, TX, AZ) | R-30 to R-49 | R-13 to R-15 | R-13 |

| Zone 3-4 (Mid-Atlantic, Southeast) | R-38 to R-60 | R-13 to R-21 | R-19 to R-25 |

| Zone 5-6 (Northeast, Midwest) | R-49 to R-60 | R-20 to R-21 | R-25 to R-30 |

| Zone 7-8 (Northern MN, WI, ME) | R-49 to R-60 | R-21+ | R-25 to R-30 |

Check your exact climate zone at the DOE’s Energy Saver website. In colder zones (5-8), investing in closed-cell spray foam for walls often pays back faster because you get more R-value per inch without increasing wall thickness. To accurately estimate insulation job costs, contractors can use a labor cost calculator to factor in crew time for each insulation method.

Spray foam insulation costs $1.50-$3.50 per square foot installed, blown-in runs $0.60-$1.50, and fiberglass batts cost $0.30-$1.00. However, long-term energy savings, lifespan, and avoided air sealing costs change the total cost picture significantly.

| Insulation Type | Material Cost/Sq Ft | Installed Cost/Sq Ft | Cost for 1,000 Sq Ft Attic |

| Closed-cell spray foam | $1.00-$1.50 | $2.00-$3.50 | $2,000-$3,500 |

| Open-cell spray foam | $0.50-$0.75 | $1.50-$2.00 | $1,500-$2,000 |

| Blown-in cellulose | $0.25-$0.50 | $0.60-$1.20 | $600-$1,200 |

| Blown-in fiberglass | $0.30-$0.50 | $0.70-$1.50 | $700-$1,500 |

| Fiberglass batts | $0.15-$0.40 | $0.30-$1.00 | $300-$1,000 |

“Blown-in insulation is less pricey than spray foam alternatives upfront, but spray foam offers better energy savings and a longer life span,” reports Angi.

| Factor | Spray Foam | Blown-In | Batts |

| Lifespan | 80+ years | 20-30 years | 15-25 years |

| Energy savings | 30-50% reduction | 15-25% reduction | 10-20% reduction |

| Payback period | 5-7 years | 3-5 years | 2-4 years |

| Settling over time | None | 10-20% (cellulose) | None (if undisturbed) |

| Additional air sealing needed | No | Yes | Yes |

Spray foam typically pays for itself within five to seven years through energy savings in cold climates and lasts 80+ years without degradation. Blown-in cellulose may settle 10-20% over time, requiring periodic top-offs. Fiberglass batts can lose effectiveness faster if exposed to moisture or physical disturbance.

For insulation contractors pricing these jobs, using professional quoting software helps generate accurate estimates that account for material type, labor complexity, and total square footage. Faster quotes mean more closed deals.

Manage Your Insulation Jobs Without the Scheduling Headaches

Running an insulation business means juggling material orders, crew schedules, and customer appointments across different job types. FieldCamp brings scheduling, dispatching, estimates, and invoicing into one platform so you spend less time on admin and more time on installs.

The best insulation type varies by where you are installing it in your home. Attic retrofits favor blown-in, walls depend on whether they are open or closed, and below-grade spaces almost always benefit from closed-cell spray foam for its moisture resistance.

Best choice for attic retrofit: Blown-in cellulose or fiberglass.

Blown-in insulation covers the entire attic floor evenly, filling around joists, wiring, and pipes without gaps. It can be added on top of existing insulation to boost R-value.

Best choice for unvented attic (conditioned): Closed-cell spray foam on the roof deck.

If you want to bring your attic into the conditioned space (turning it into usable area), spray foam on the underside of the roof deck creates an air-sealed, insulated barrier.

You can combine methods. Apply two inches of closed-cell spray foam to the roof deck for air sealing (R-12), then fill the remaining rafter depth with fiberglass batts for cost-effective R-value. This “flash-and-batt” approach balances performance and budget.

Best for new construction walls: Spray foam or fiberglass batts.

In open stud bays during new construction, both spray foam and batts work well. Spray foam costs more but eliminates air leaks. Batts cost less but require careful fitting.

Best for existing walls (retrofit): Dense-pack blown-in cellulose.

Injecting dense-pack cellulose through small drill holes fills closed wall cavities completely without removing drywall. It is the most practical retrofit solution. Contractors handling wall retrofits can use AI-powered scheduling to assign crews with the right equipment and certifications automatically.

Best choice: Closed-cell spray foam.

Below-grade spaces face moisture intrusion from soil and concrete. Closed-cell spray foam simultaneously insulates and blocks moisture vapor. It eliminates the need for a separate vapor barrier on foundation walls.

“For hot climates like Phoenix, spray foam is often the best option due to its superior air sealing and thermal resistance,” notes Koala Insulation.

Best choice: Fiberglass batts (budget) or blown-in insulation (performance).

Garages with exposed stud bays are easy to insulate with batts. For attached garages where air sealing from vehicle fumes matters, spray foam on the shared wall with living space adds both insulation and a fume barrier.

| If this describes you… | Consider this insulation |

| Retrofitting an old attic without removing anything | Blown-in cellulose or fiberglass |

| Insulating existing walls without tearing out drywall | Dense-pack blown-in cellulose |

| New construction with open stud bays on a budget | Fiberglass batts |

| Basement or crawl space with moisture concerns | Closed-cell spray foam |

| Want maximum energy savings regardless of budget | Closed-cell spray foam throughout |

| Finishing an attic into livable space | Spray foam on roof deck |

| Garage insulation with exposed framing | Fiberglass batts |

| Extreme cold climate (Zone 6-8) | Spray foam for walls, blown-in for attic floor |

Spray foam insulation raises the most health and safety questions due to chemical off-gassing during installation, while cellulose and fiberglass are generally considered safer for indoor air quality. All three types have environmental trade-offs worth understanding.

Spray foam insulation uses isocyanate chemicals that produce volatile organic compounds (VOCs) during application and curing. Occupants must vacate the home during installation and for 24-72 hours after, depending on the product.

Once fully cured, closed-cell and open-cell spray foam are chemically stable and do not continue off-gassing. However, improperly mixed spray foam can remain tacky and off-gas indefinitely.

Warning: Always hire a certified spray foam contractor. Improperly installed spray foam is the number one source of spray foam complaints. A skilled contractor using digital checklists and forms and documented procedures ensures proper mixing ratios, temperature, and application thickness.

Cellulose blown-in insulation is treated with borate-based fire retardants that also resist mold, insects, and rodents. It is made from roughly 85% post-consumer recycled paper.

Fiberglass (both blown-in and batts) is naturally non-combustible. It does not support mold growth but can trap moisture against surfaces if improperly installed without a vapor retarder.

| Factor | Spray Foam | Blown-In Cellulose | Fiberglass |

| Recycled content | Low | High (85%+ post-consumer) | Moderate (20-30%) |

| Manufacturing energy | High | Low | Moderate |

| Chemical concerns | Isocyanate during install | Minimal (borate treatments) | Minimal |

| Longevity (less replacement waste) | 80+ years | 20-30 years | 15-25 years |

| Carbon footprint | Higher upfront, offset by energy savings | Lowest | Moderate |

If indoor air quality and environmental impact are top priorities, blown-in cellulose offers the best balance of safety, recycled content, and thermal performance. For maximum long-term energy savings that offset the initial environmental cost, spray foam wins over its 80+ year lifespan.

Choosing the right insulation requires evaluating four factors: your home’s current condition, your climate zone, your budget, and your specific goals (comfort, energy savings, soundproofing, or moisture control). Here is a step-by-step process.

Step 1: Assess current insulation → Step 2: Identify your climate zone R-value needs → Step 3: Determine application (attic, walls, crawl space) → Step 4: Set your budget → Step 5: Choose insulation type

1. Is this new construction with open framing?

2. Is this an attic retrofit?

3. Is this an existing wall retrofit?

4. Is this a basement or crawl space?

[ ] Check current insulation type and R-value in attic, walls, and basement

[ ] Identify your DOE climate zone

[ ] Get an energy audit or blower door test

[ ] Note areas with drafts, hot/cold spots, or moisture issues

[ ] Set a total budget for the insulation project

[ ] Get quotes from at least two to three contractors

[ ] Verify contractor licensing, insurance, and certifications

[ ] Confirm estimated R-value after installation

[ ] Schedule post-install inspection or blower door retest

HD Solutions summarizes the decision well: “If you value maximum energy savings and long-term durability, spray foam is the best choice. If you are looking for an affordable, reliable option, batt insulation delivers solid results. If your home requires flexible coverage, blown-in insulation provides an excellent balance of performance and cost.”

For insulation contractors managing multiple job types and customer appointments, AI-powered dispatch scheduling automatically assigns crews based on skills, equipment, and location. This keeps attic blow-ins, spray foam installs, and batt jobs running on time without manual dispatching. Contractors handling route optimization across multiple job sites see 35% less drive time on average.

Get the complete insulation job estimate template. Includes line items for spray foam, blown-in, and batt insulation, labor rates, material quantities, and customer-ready formatting. Contractors can also explore construction estimate templates and HVAC estimate templates for related trade work.

[Download Now]

Insulation contractors juggle multiple job types, each requiring different equipment, crew skills, and time windows. Managing spray foam crews separately from blown-in teams, tracking material inventory, and sending accurate estimates quickly is a daily challenge.

With FieldCamp’s AI-powered dispatch scheduling and route optimization, insulation businesses can:

Whether you run a two-person crew or a growing operation, modern field service management tools help you take on 30-40% more jobs with the same team.

Ready to Grow Your Insulation Business?

See how FieldCamp helps insulation contractors schedule more jobs, dispatch the right crews, and eliminate paperwork. Join field service businesses saving hours every week on scheduling and dispatching.

Choosing between spray foam vs blown-in vs batt insulation comes down to five key factors:

No matter which insulation type you choose, proper installation is the single biggest factor in real-world performance. A perfectly installed R-13 batt outperforms a poorly installed R-19 spray foam job every time.

For insulation contractors looking to manage more jobs, reduce scheduling headaches, and deliver faster estimates, FieldCamp’s AI-powered platform brings scheduling, dispatching, quoting, and invoicing together in one system.

Spray foam is liquid polyurethane that expands to fill and seal cavities, delivering R-3.7-6.7 per inch. Blown-in is loose-fill fiberglass or cellulose pneumatically installed for R-2.3-4.3 per inch. Batt insulation comes in pre-cut fiberglass blankets rated R-2.9-3.8 per inch. Each uses different materials, installation methods, and costs.

Closed-cell spray foam has the highest R-value at R-6.0 to R-6.7 per inch. Open-cell spray foam provides R-3.5-3.7 per inch. Cellulose blown-in delivers R-3.2-3.8 per inch. Fiberglass batts and blown-in range from R-2.2 to R-3.8 per inch. Higher R-value per inch means you need less material thickness to reach your target insulation level.

Spray foam costs two to three times more than blown-in or batts upfront. However, it lasts 80+ years, eliminates air leaks without additional sealing, and typically reduces heating and cooling costs by 30-50%. In cold climates (Zones 5-8) with high energy bills, spray foam often pays for itself within five to seven years. For milder climates or tight budgets, blown-in offers strong value.

Yes. Blown-in insulation can be added directly over existing batts in attics to increase total R-value. There is no need to remove the old batts unless they are wet, moldy, or contaminated. This is one of the most cost-effective ways to boost energy efficiency in an older home.

Fiberglass and cellulose blown-in insulation pose minimal indoor air quality risks once installed. Cellulose is treated with borate, which is low-toxicity. Spray foam releases VOCs during installation and requires 24-72 hours of cure time before occupants re-enter. Once cured, properly installed spray foam does not off-gas.

For most US attic retrofits, blown-in cellulose or fiberglass is the best choice. It covers the attic floor evenly, fills around obstructions, and can be added over existing insulation. For unvented attics converted into conditioned space, closed-cell spray foam applied to the roof deck is the preferred method.

Fiberglass batts are the most DIY-friendly insulation. Blown-in insulation can be DIY for attic applications using a renter blower machine from home improvement stores. Spray foam insulation always requires a licensed professional due to chemical handling, equipment requirements, and the risk of improper mixing. For contractor businesses managing multiple crews, AI-powered dispatch tools help coordinate installations efficiently.